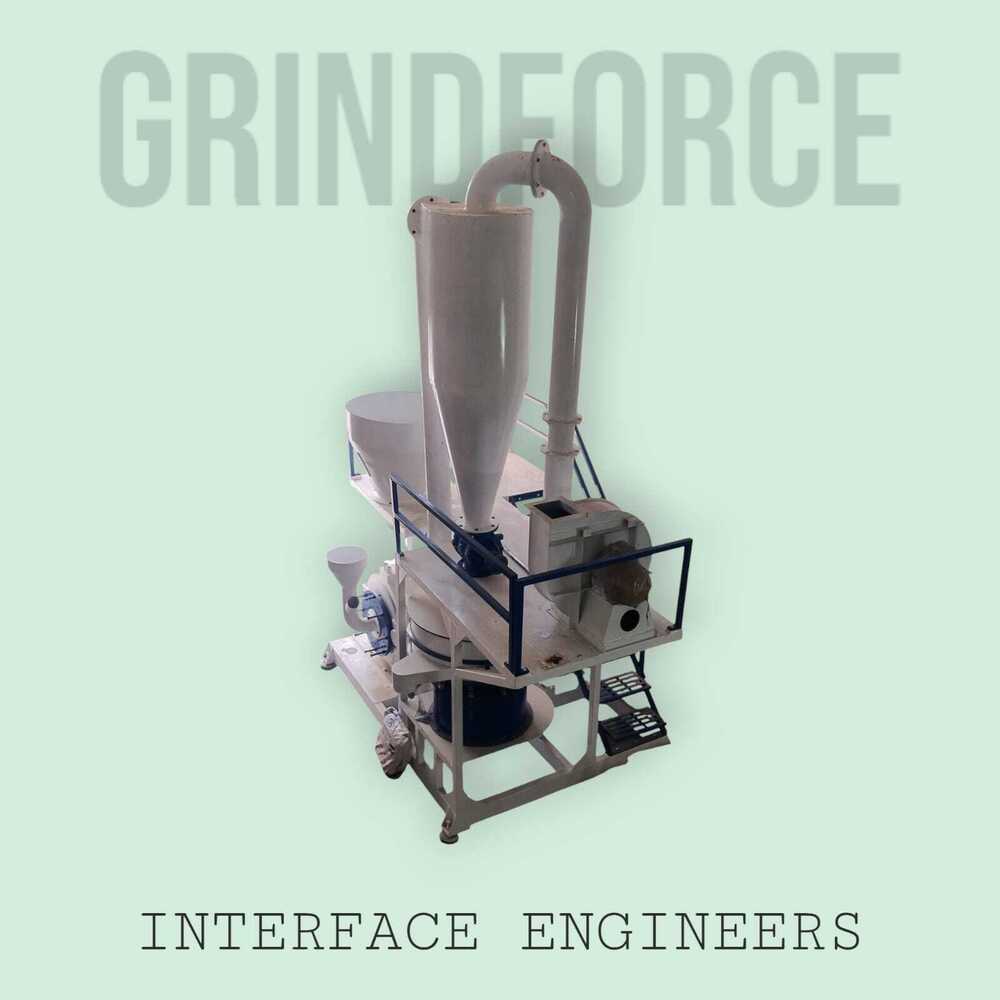

LLDPE Pulverizer Disc Blade Machine

Price 581000 INR/ Piece

LLDPE Pulverizer Disc Blade Machine Specification

- Usage

- Industrial

- Condition

- New

- Material

- Mild Steel

- Size

- 300 MM - 600 MM

- Height

- 11.5 Foot (ft)

- Power Source

- Electric

- Product Type

- INDUSTRIAL PULVERISER MACHINE

- Weight

- 1500 Kilograms (kg)

- Power(W)

- 40 Horsepower (HP)

- Power Consumption

- 220/440 Volt-Ampere (VA)

- Color

- Blue & Ivory

- Length

- 5.5 Foot (ft)

- Width

- 6 Foot (ft)

- Dimension (L*W*H)

- 11.5*5.5*5.5 Foot (ft)

LLDPE Pulverizer Disc Blade Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About LLDPE Pulverizer Disc Blade Machine

For efficient and consistent powdering of PVC andLLDPE materials, our Disc Mill Plastic Pulverizer is the ideal solution.1 Its advanced disc technology ensures optimal particledistribution and high throughput, making it indispensable for industriesrelying on finely processed PVC and LLDPE.

Superior Construction and Durability

Built with high-grade mild steel, the LLDPE Pulverizer Disc Blade Machine offers exceptional strength and resistance to wear. Its heavy-duty construction supports continuous industrial use while maintaining precision and reliability. The sturdy frame ensures stability during operation and increases the service life of the machine.

Optimal Power and Efficiency

Equipped with a 40 Horsepower electric motor, this machine delivers powerful grinding capabilities for demanding industrial applications. The power consumption of 220/440 Volt-Ampere is designed to match high production requirements with energy efficiency, optimizing operational costs while maintaining consistent output.

Versatile Industrial Applications

The LLDPE Pulverizer Disc Blade Machine is ideal for a wide range of industrial sectors, including manufacturing, plastic recycling, and material processing facilities. With support for varying disc sizes (300600 MM), it caters to different processing needs. Its availability in India through various channels makes it accessible for distributors, suppliers, and end-users alike.

FAQs of LLDPE Pulverizer Disc Blade Machine:

Q: How does the LLDPE Pulverizer Disc Blade Machine operate?

A: The machine utilizes a high-powered, 40 HP electric motor to rotate pulverizer discs (ranging from 300 MM to 600 MM), efficiently grinding materials such as LLDPE into fine particles. It is powered by 220/440 VA and is designed for seamless, continuous industrial use.Q: What are the main applications of this pulverizer disc blade machine?

A: This machine is primarily used in industrial sectors for pulverizing plastic resins like LLDPE, aiding in manufacturing and recycling processes. Its robust design also makes it suitable for processing a variety of other polymers and materials.Q: When should I consider using this machine in my factory?

A: You should use this machine when you require high-capacity grinding and pulverization of materials, especially in large-scale industrial settings. It is particularly beneficial when consistent, fine output and heavy-duty performance are needed.Q: Where can I install the LLDPE Pulverizer Disc Blade Machine?

A: Due to its substantial dimensions (11.5 x 5.5 x 5.5 ft) and weight (1500 kg), the machine should be installed in a spacious and stable industrial area with suitable electrical connections to handle the 220/440 VA power requirements.Q: What is the process for maintaining the machine?

A: Regular cleaning after each use, timely inspection and replacement of disc blades, and lubrication of moving parts ensure optimal performance. Electrical components should also be checked periodically to ensure safe, reliable operation.Q: What are the benefits of using this pulverizer machine?

A: The machine offers high productivity, reduced manual labor, consistent particle size, and enhanced efficiency for industrial applications. Its durable mild steel body and energy-efficient operation ensure a lower total cost of ownership.Q: Can this machine be sourced, exported, or supplied across India?

A: Yes, the LLDPE Pulverizer Disc Blade Machine is available for distributors, exporters, importers, manufacturers, service providers, suppliers, traders, and wholesalers throughout India, ensuring broad accessibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

Lldpe Plastic Pulverizer Machine Manufacturer

Price 421000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Power Consumption : 30 Horsepower (HP)

Weight : 2000 Kilograms (kg)

Usage : Commercial

LLDPE Granuel Pulverizer Machine

Price 421000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Power Consumption : 220/440 VoltAmpere (VA)

Weight : 1850 Kilograms (kg)

Usage : Commercial

Lldpe Pulverizer Machine 100kg

Price 390000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Power Consumption : 220/440 Volt (V)

Weight : 1750 Kilograms (kg)

Usage : Commercial

Lldpe Pulverizer Disc Blade

Price 581000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Power Consumption : 220/440 VoltAmpere (VA)

Weight : 1500 Kilograms (kg)

Usage : Industrial

Send Inquiry

Send Inquiry