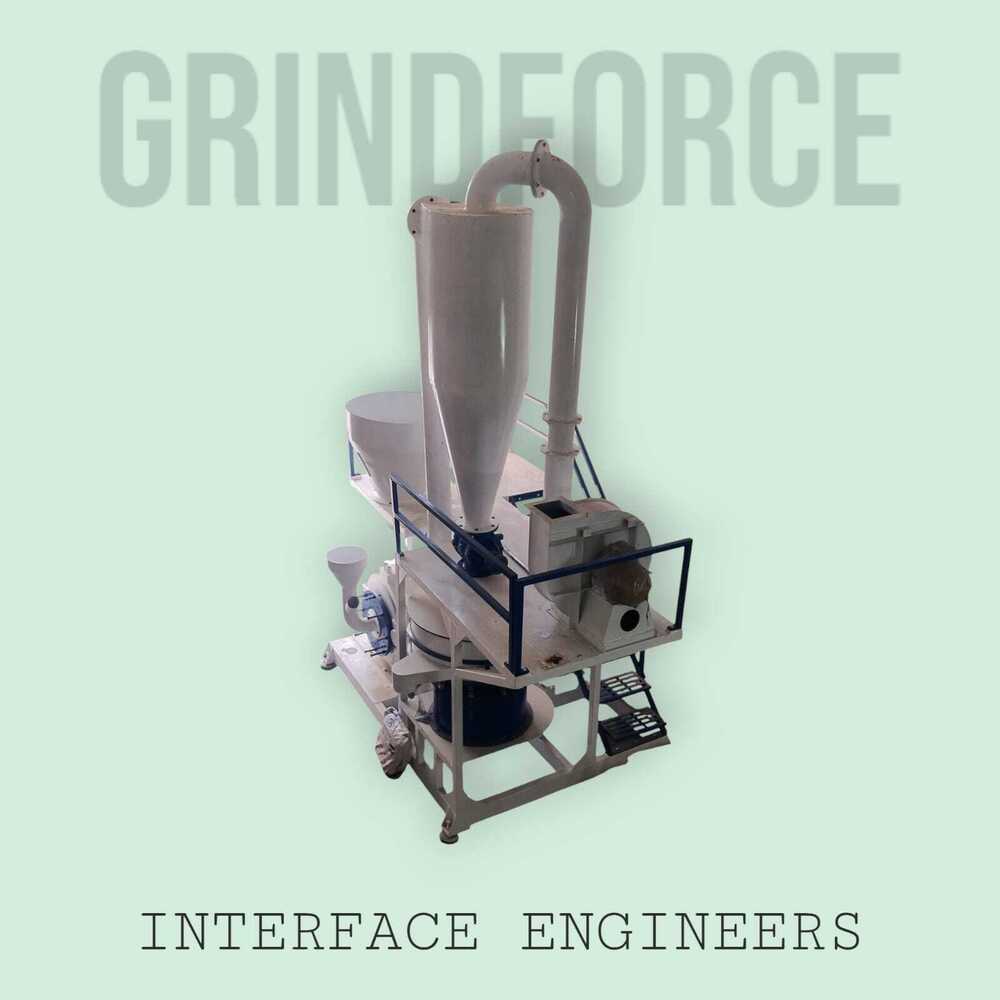

Lldpe Plastic Pulverizer Machine Manufacturer

Price 421000 INR/ Piece

Lldpe Plastic Pulverizer Machine Manufacturer Specification

- Usage

- Commercial

- Condition

- New

- Material

- Mild Steel

- Size

- 300 MM - 600 MM

- Height

- 11.5 Foot (ft)

- Power Source

- Electric

- Product Type

- INDUSTRIAL PULVERISER MACHINE

- Weight

- 2000 Kilograms (kg)

- Power(W)

- 25 Horsepower (HP)

- Power Consumption

- 30 Horsepower (HP)

- Color

- White and Blue

- Width

- 6 Foot (ft)

- Length

- 5.5 Foot (ft)

- Dimension (L*W*H)

- 11.5*5.5*5.5 Foot (ft)

Lldpe Plastic Pulverizer Machine Manufacturer Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Lldpe Plastic Pulverizer Machine Manufacturer

For efficient and consistent powdering of PVC andLLDPE materials, our Disc Mill Plastic Pulverizer is the ideal solution.1 Its advanced disc technology ensures optimal particledistribution and high throughput, making it indispensable for industriesrelying on finely processed PVC and LLDPE.

Engineered for Industrial-Scale Performance

Our LLDPE Plastic Pulverizer Machine is tailored for demanding applications in commercial environments. Built from robust mild steel, it offers both durability and efficiency. The electric-powered design facilitates smooth operation, while its substantial dimensions and weight provide stability for continuous pulverizing tasks. Suitable for large-scale manufacturers, distributors, and service providers, this machine brings reliability to your production line.

Versatile Applications and Easy Maintenance

Designed for a range of operationspulverizing, recycling, and preparing materialsthe machine adapts seamlessly to various plastic-processing needs. The thoughtful design ensures easy access for maintenance, with minimal downtime. Its powerful motor and high-quality build make it a smart investment for businesses seeking efficiency, reliability, and long-term performance in their plastic processing operations.

FAQs of Lldpe Plastic Pulverizer Machine Manufacturer:

Q: How do I operate the LLDPE Plastic Pulverizer Machine for optimal performance?

A: Begin by connecting the machine to an appropriate electric power source. Feed LLDPE plastic material within the recommended size range into the input hopper. Adjust operational settings as required. Regularly monitor the machine during use to ensure smooth functioning and safety.Q: What materials can the machine process efficiently?

A: This machine is specifically designed to pulverize LLDPE, but it is also compatible with similar lightweight polymers and plastic materials commonly used in commercial and industrial settings.Q: When should maintenance be performed on the pulverizer?

A: Routine maintenance should be conducted after every substantial production period or as listed in the manufacturers manual, focusing on blade sharpness, lubrication, and system cleanliness to sustain optimal results and longevity.Q: Where can this pulverizer be installed within my facility?

A: Ensure the installation site is spacious, accommodating the machines footprint (11.5 x 5.5 x 5.5 ft) and allowing easy access for operation and upkeep. Place on a stable, level surface, ideally in well-ventilated zones of your plastic processing facility.Q: What is the process for switching between different sizes of plastic materials?

A: Adjustments can be made to the input size settings, which support plastic pieces ranging from 300 mm to 600 mm. Always refer to the operation manual for guidelines on changing settings and preparing the machine for different material sizes.Q: How does the machine benefit commercial plastic processing?

A: It enhances productivity through high-capacity pulverizing, consistent performance from its 25 HP motor, and rugged mild steel construction. Businesses benefit from reduced processing times and increased output efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

75 Hp Lldpe Pulverizer Machine

Price 861000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Condition : New

Weight : 2500 Kilograms (kg)

Material : Mild Steel

Lldpe Granules Pulverizer Machine

Price 531000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Condition : New

Weight : 1800 Kilograms (kg)

Material : Mild Steel

600 MM DIA LLDPE Pulverizer Machine

Price 841000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Condition : New

Weight : 2500 Kilograms (kg)

Material : Mild Steel

Lldpe Plastic Pulverizer Machine

Price 381000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Condition : New

Weight : 1500 Kilograms (kg)

Material : Mild Steel

Send Inquiry

Send Inquiry