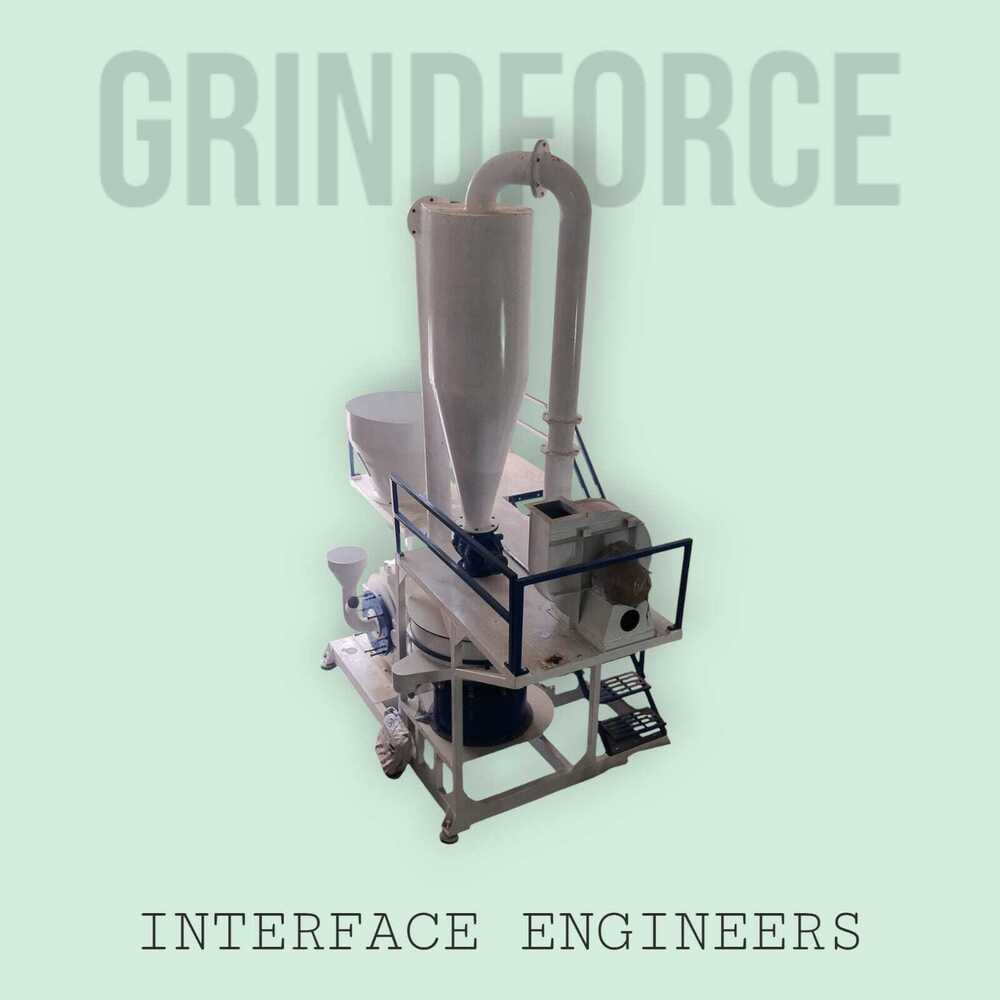

LLDPE Granuel Pulverizer Machine

Price 421000 INR/ Piece

LLDPE Granuel Pulverizer Machine Specification

- Usage

- Commercial

- Condition

- New

- Size

- 400 MM

- Material

- Mild Steel

- Height

- 11.5 Foot (ft)

- Product Type

- INDUSTRIAL LLDPE PULVERISER MACHINE

- Power Source

- Electric

- Power(W)

- 40 Horsepower (HP)

- Weight

- 1850 Kilograms (kg)

- Power Consumption

- 220/440 Volt-Ampere (VA)

- Color

- White and Blue

- Length

- 5.5 Foot (ft)

- Width

- 5.5 Foot (ft)

- Dimension (L*W*H)

- 11.5*5.5*5.5 Foot (ft)

LLDPE Granuel Pulverizer Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About LLDPE Granuel Pulverizer Machine

The Plastic Pulverizer Machine (Disc Mill Type) is expertlyengineered to efficiently process PVC and LLDPE materials into fine,consistent powder. Its precision disc-based grinding system is ideal forproducing high-quality material essential for rotational molding, masterbatch,and other specialized applications.

Efficient and Reliable Industrial Pulverizing

Engineered for commercial usage, the LLDPE Granuel Pulverizer Machine ensures steady and high-speed processing of LLDPE granules into fine powder. The robust mild steel body and electric-powered 40 HP motor allow consistent operation while maintaining energy efficiency. Its sturdy construction reduces vibration for quieter operation, promising reliability in demanding environments.

Versatility in Application and Installation

This pulverizer features versatile installation dimensions (11.5x5.5x5.5 ft) to suit various industrial locations. Its weight and size balance ease of placement with stability during operation. The machines dual-tone white and blue finish not only adds a modern touch but also offers easy maintenance, supporting factories, workshops, and production units across India.

FAQs of LLDPE Granuel Pulverizer Machine:

Q: How does the LLDPE Granuel Pulverizer Machine operate?

A: The machine processes LLDPE granules by using a high-powered 40 HP electric motor to drive precision blades within its mild steel chamber, reducing plastic granules to fine powder suitable for commercial manufacturing needs.Q: What are the benefits of using this pulverizer for my business?

A: Using this pulverizer boosts productivity by automating the granule powdering process, ensuring uniform particle size, minimizing manual labor, and conserving energy with its efficient 220/440 VA electric power consumption, all of which can improve your operational efficiency.Q: Where can the LLDPE Granuel Pulverizer Machine be installed?

A: Given its compact dimensions and robust design, the machine fits conveniently into commercial or industrial setups, such as manufacturing plants or recycling centers, especially those located in India.Q: When is the right time to service this machine?

A: Routine maintenance should be carried out based on operational hours and manufacturer recommendations. Regularly checking components after set production intervals will extend machine life and maintain productivity.Q: What is the process involved in pulverizing LLDPE granules with this machine?

A: The process involves feeding LLDPE granules into the machine, where powerful blades spin at high speeds to pulverize the material into fine powder. The output can be collected for immediate commercial or industrial use.Q: How does the size and weight of the pulverizer impact its installation?

A: The sturdy construction (1850 kg, 11.5x5.5x5.5 ft) provides stability, reducing vibration during operation. Its manageable width and length allow seamless integration into new or existing industrial layouts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

Lldpe Plastic Pulverizer Machine

Price 381000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : White and Blue

Material : Mild Steel

Weight : 1500 Kilograms (kg)

Usage : Commercial

Plastic Scrap Pulverizer

Price 451000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : White and Blue

Material : Mild Steel

Weight : 1500 Kilograms (kg)

Usage : Industrial

Lldpe Pulverizer Disc Blade

Price 581000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue & Ivory

Material : Mild Steel

Weight : 1500 Kilograms (kg)

Usage : Industrial

600 MM DIA LLDPE Pulverizer Machine

Price 841000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : White and Blue

Material : Mild Steel

Weight : 2500 Kilograms (kg)

Usage : Commercial

Send Inquiry

Send Inquiry