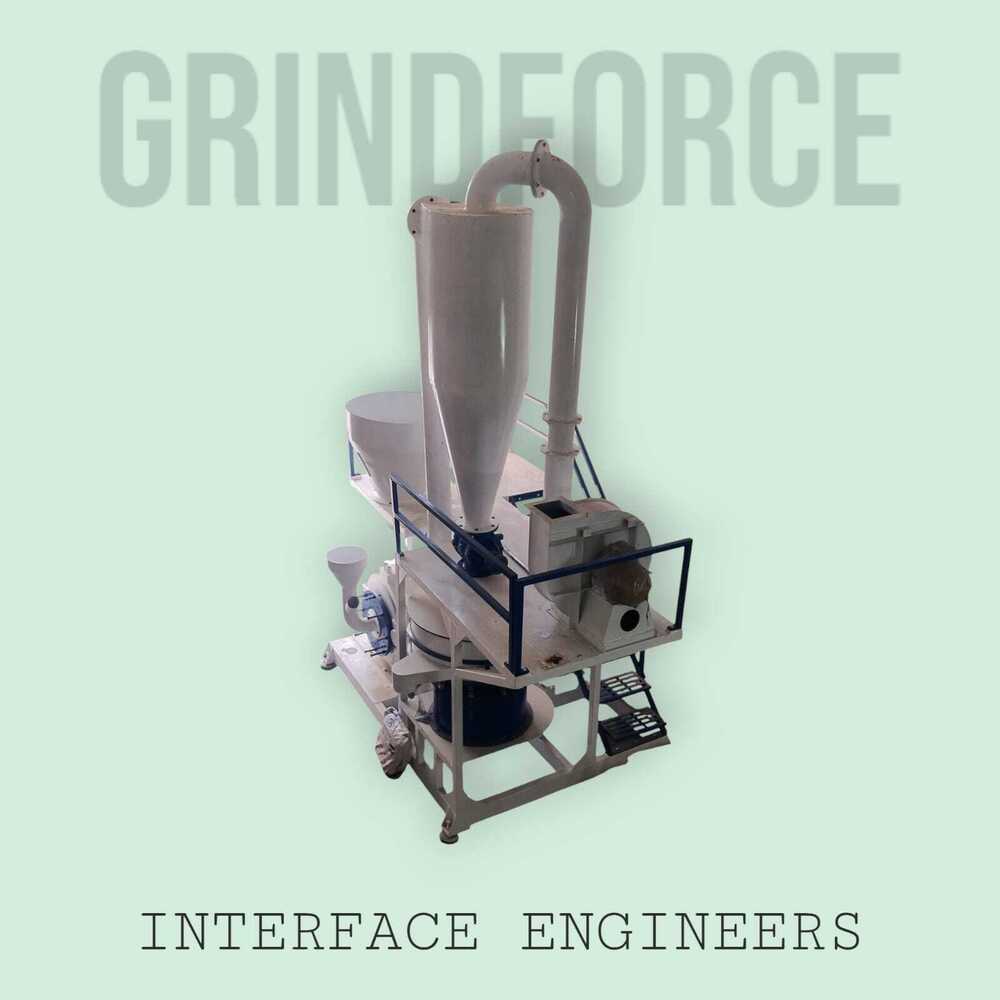

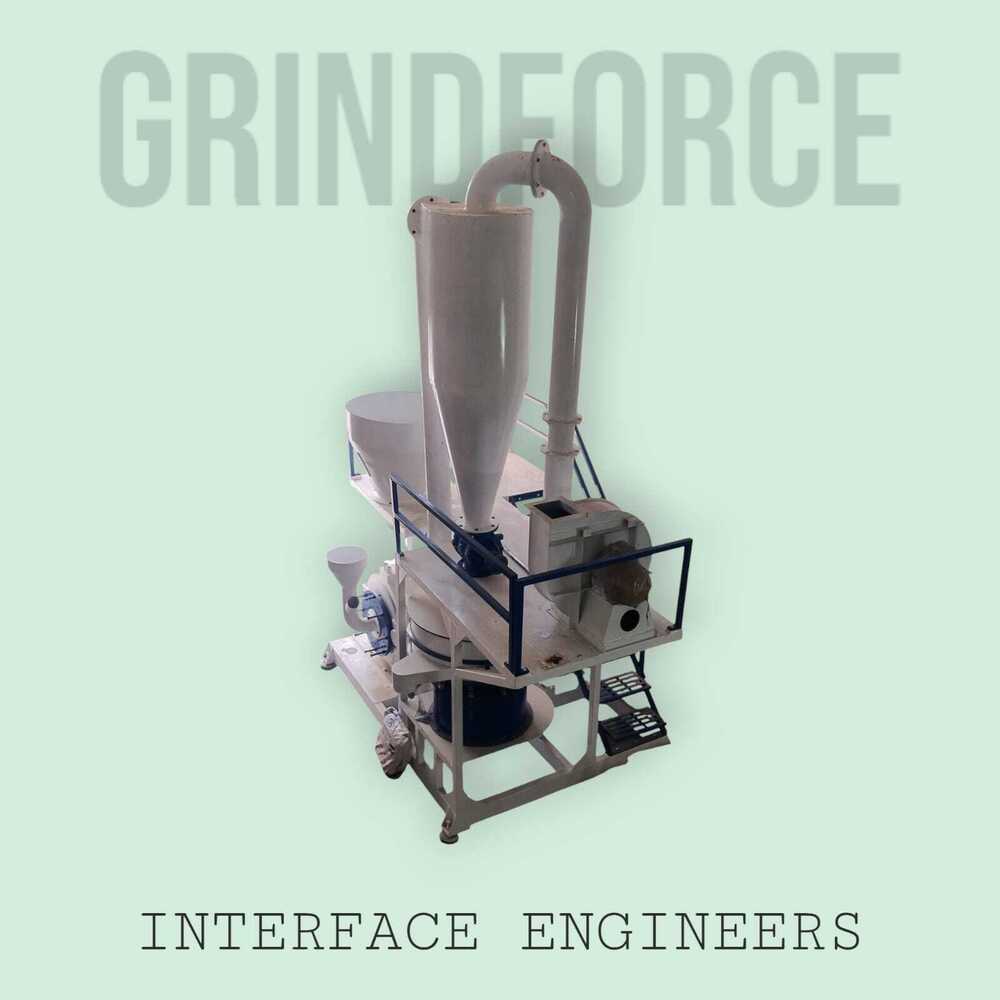

Lldpe Pulverizer Disc Blade

Price 581000 INR/ Piece

Lldpe Pulverizer Disc Blade Specification

- Usage

- Industrial

- Condition

- New

- Material

- Mild Steel

- Size

- 300 MM - 600 MM

- Height

- 11.5 Foot (ft)

- Product Type

- INDUSTRIAL PULVERISER MACHINE

- Power Source

- Electric

- Weight

- 1500 Kilograms (kg)

- Power(W)

- 40 Horsepower (HP)

- Color

- Blue & Ivory

- Power Consumption

- 220/440 Volt-Ampere (VA)

- Width

- 6 Foot (ft)

- Length

- 5.5 Foot (ft)

- Dimension (L*W*H)

- 6FT * 5.5 FT * 15 FT Foot (ft)

Lldpe Pulverizer Disc Blade Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Lldpe Pulverizer Disc Blade

For efficient and consistent powdering of PVC andLLDPE materials, our Disc Mill Plastic Pulverizer is the ideal solution.1 Its advanced disc technology ensures optimal particledistribution and high throughput, making it indispensable for industriesrelying on finely processed PVC and LLDPE.

Optimized Performance for Industrial Pulverizing

The LLDPE Pulverizer Disc Blade delivers exceptional performance in pulverizing and milling industrial plastics such as LLDPE granules. Its dimensions and weight are engineered for machines requiring heavy-duty, high-speed disc action. Paired with a 40 HP electric power source, it provides efficient material processing, reducing downtime and maximizing productivity.

Built to Last with Quality Materials

Crafted from premium mild steel, the disc blade is designed to withstand rigorous use. Its construction ensures resistance to wear, guaranteeing a longer service life and optimal pulverizing efficiency. This reliability makes it a top choice for continuous industrial operations where equipment performance is critical.

Versatile Application Across Industries

This disc blade supports a wide range of applications, serving as a key component for manufacturers, exporters, and service providers. Used mainly in the plastics industry, it is suitable for firms involved in supply, trade, or servicing of industrial machinery across India and globally.

FAQs of Lldpe Pulverizer Disc Blade:

Q: How is the LLDPE Pulverizer Disc Blade installed and operated?

A: The disc blade is installed into the pulverizer machine, fitting models with sizes ranging from 300 mm to 600 mm. Once securely fitted, it operates using a 40 HP electric motor and requires a 220/440 VA power supply. Professional installation is recommended for safe and efficient setup.Q: What materials can the LLDPE Pulverizer Disc Blade process?

A: Designed primarily for Low Linear Density Polyethylene (LLDPE), the disc blade is also suitable for similar plastic polymers, ensuring fine, consistent grinding crucial for plastic manufacturing and recycling operations.Q: When should the disc blade be replaced for optimal performance?

A: Routine maintenance checks are suggested to monitor wear. Depending on usage frequency and the abrasiveness of processed materials, replacements may be considered after significant dulling or reduction in throughput efficiency, typically after extended cycles of heavy operation.Q: Where can the LLDPE Pulverizer Disc Blade be sourced in India?

A: The blade is widely available from reputable distributors, exporters, importers, manufacturers, service providers, suppliers, traders, and wholesalers within India. Many companies also offer international shipping and after-sales support.Q: What are the process steps for using this disc blade in industrial applications?

A: Begin by safely installing the disc blade into a compatible pulverizer. Ensure the power supply matches the required 220/440 VA and start the machine, maintaining recommended operational parameters for plastics pulverization. Routine cleaning and inspection are essential to maintain efficiency.Q: What are the main benefits of using this disc blade?

A: Utilizing this blade ensures precise and consistent pulverization, high throughput, and reduced machine downtime. The mild steel construction translates to longevity and reduced replacement costs, making it a reliable asset in industrial plastic processing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

Lldpe Granules Pulverizer Machine

Price 531000 INR / Piece

Minimum Order Quantity : 1 Piece

Power(W) : 50 Horsepower (HP)

Usage : Commercial

Size : 300 MM 600 MM DISC

Dimension (L*W*H) : 7*7.5*15 Foot (ft)

Lldpe Pulverizer Machine 100kg

Price 390000 INR / Piece

Minimum Order Quantity : 1 Piece

Power(W) : 25 Horsepower (HP)

Usage : Commercial

Size : 350 MM

Dimension (L*W*H) : 7*6*15 Foot (ft)

Lldpe Plastic Pulverizer Machine

Price 471000 INR / Piece

Minimum Order Quantity : 1 Piece

Power(W) : 40 Horsepower (HP)

Usage : Industrial

Size : 300 MM 600 MM DISC

Dimension (L*W*H) : 11.5*5.5*5.5 Foot (ft)

LLDPE Granuel Pulverizer Machine

Price 421000 INR / Piece

Minimum Order Quantity : 1 Piece

Power(W) : 40 Horsepower (HP)

Usage : Commercial

Size : 400 MM

Dimension (L*W*H) : 11.5*5.5*5.5 Foot (ft)

Send Inquiry

Send Inquiry