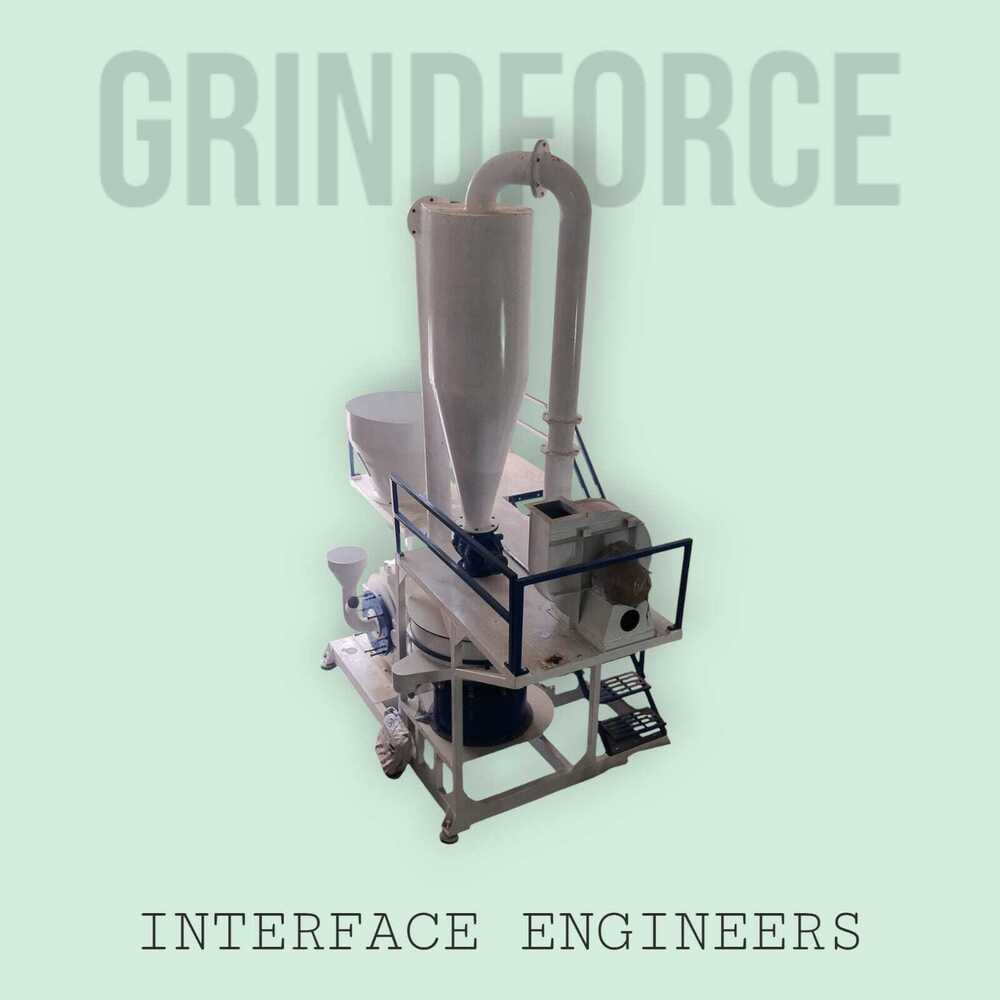

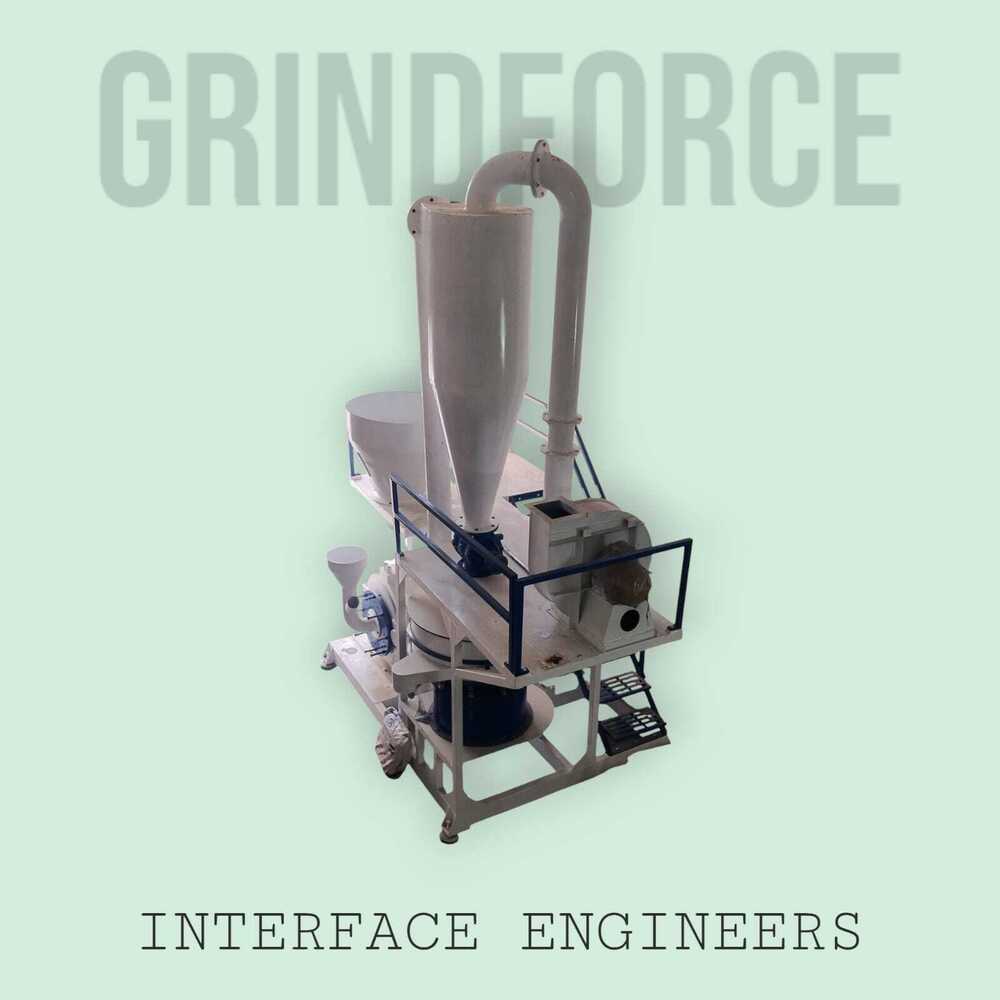

Lldpe Granules Pulverizer Machine

Price 531000 INR/ Piece

Lldpe Granules Pulverizer Machine Specification

- Usage

- Commercial

- Condition

- New

- Size

- 300 MM - 600 MM DISC

- Material

- Mild Steel

- Height

- 15 Foot (ft)

- Power Source

- Electric

- Product Type

- INDUSTRIAL LLDPE PULVERISER MACHINE

- Power(W)

- 50 Horsepower (HP)

- Weight

- 1800 Kilograms (kg)

- Color

- White

- Power Consumption

- 220/440 Volt-Ampere (VA)

- Width

- 7.5 Foot (ft)

- Length

- 7 Foot (ft)

- Dimension (L*W*H)

- 7*7.5*15 Foot (ft)

Lldpe Granules Pulverizer Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Lldpe Granules Pulverizer Machine

The Plastic Pulverizer Machine (Disc Mill Type) is expertlyengineered to efficiently process PVC and LLDPE materials into fine,consistent powder. Its precision disc-based grinding system is ideal forproducing high-quality material essential for rotational molding, masterbatch,and other specialized applications.

Versatile Commercial Pulverizing Solution

This LLDPE Granules Pulverizer Machine is designed to meet the demanding requirements of bulk plastic processing. Whether youre a distributor, manufacturer, or service provider, its 15-foot height and broad disc size range ensure adaptability to varied operational needs. The sturdy mild steel build guarantees longevity and minimal maintenance, supporting consistent commercial use.

Powerful Electric Performance

Driven by a 50 HP motor and compatible with both 220V and 440V power sources, this pulverizer delivers reliable, high-output performance. Its efficient electric operation makes it a cost-effective option for large-scale processing, while supporting safe and continuous operation in commercial environments.

FAQs of Lldpe Granules Pulverizer Machine:

Q: How is the LLDPE Granules Pulverizer Machine installed and operated?

A: The machine should be installed on a leveled surface with proper electrical connections to either a 220V or 440V electric supply. After installation, load the LLDPE granules, set the disc size (300 mm 600 mm), and start the machine using the control panel. Trained staff should handle daily operations for safety and efficiency.Q: What types of materials can this pulverizer process?

A: While optimized for LLDPE granules, this machine can also process similar thermoplastic materials owing to its adjustable disc size and robust design. Its widely used in recycling units and plastic manufacturing industries across India.Q: When should routine maintenance be performed?

A: Routine maintenance is recommended every 3-6 months based on usage intensity. Regular checks ensure the discs and motor stay in optimal condition, preventing breakdowns and prolonging equipment lifespan.Q: Where is this machine best utilized?

A: The pulverizer is ideal for commercial facilities such as plastic recycling plants, granule manufacturing units, and industrial processing centers in India. Its size and power make it suitable for both large and medium-scale operations.Q: What is the process flow for using the machine?

A: Feed the LLDPE granules into the hopper, adjust the disc size as required, and activate the machine. Pulverized material is discharged through an outlet for packaging or further processing. Safety protocols and regular monitoring are recommended throughout operation.Q: How does this machine benefit your business?

A: Investing in this pulverizer enhances operational efficiency by delivering consistent particle sizes and reducing labor costs. Its durability and high capacity minimize downtime, making it a reliable addition for any distributor, manufacturer, or trader handling bulk plastics.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

Plastic Pulverizer Lldpe Machine

Price 551000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Commercial

Color : White

Material : Mild Steel

Size : 450 MM

Masterbatch Plastic Pulverizer

Price 580000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Color : White and Blue

Material : Mild Steel

Size : 300 MM 600 MM DISC

Lldpe Plastic Pulverizer Machine

Price 381000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Commercial

Color : White and Blue

Material : Mild Steel

Size : 300 MM

LLDPE Pulverizer Disc Blade Machine

Price 581000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Color : Blue & Ivory

Material : Mild Steel

Size : 300 MM 600 MM

Send Inquiry

Send Inquiry