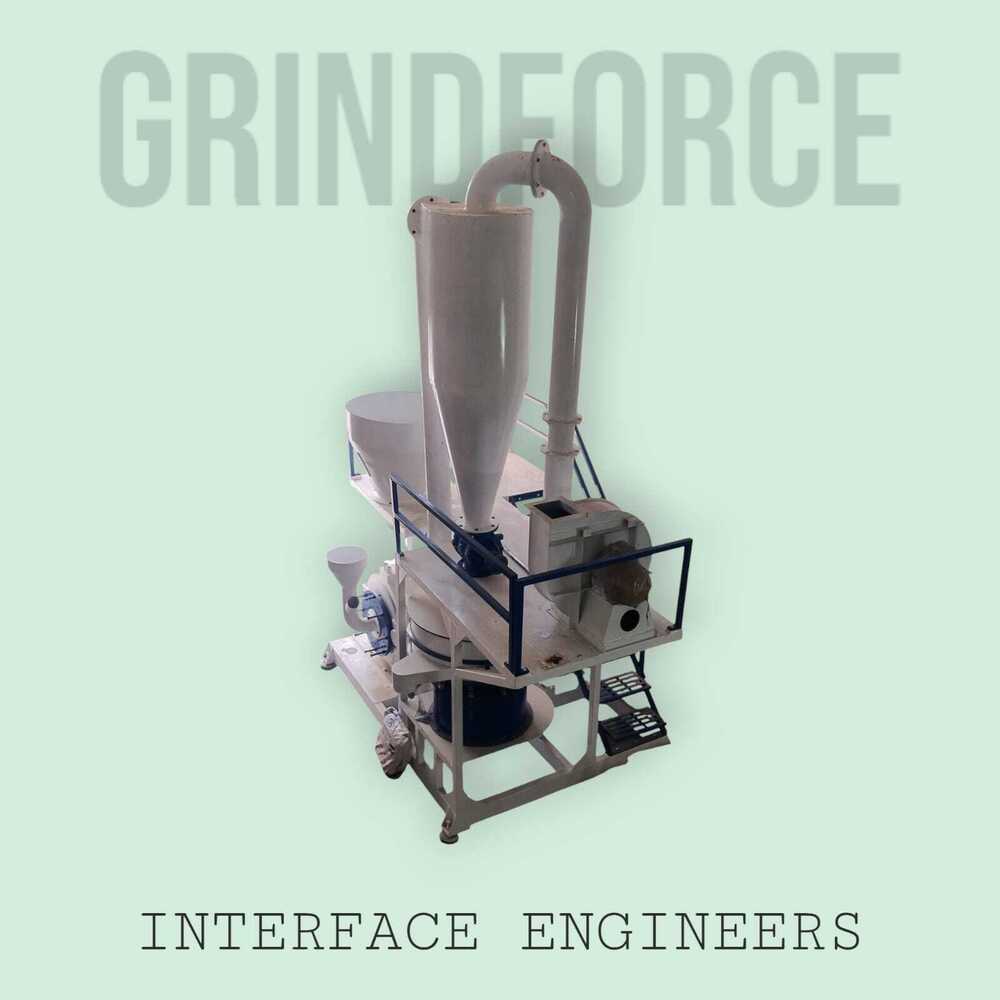

600 MM DIA LLDPE Pulverizer Machine

Price 841000 INR/ Piece

600 MM DIA LLDPE Pulverizer Machine Specification

- Usage

- Commercial

- Condition

- New

- Size

- 600 MM

- Material

- Mild Steel

- Height

- 15 Foot (ft)

- Product Type

- INDUSTRIAL LLDPE PULVERISER MACHINE

- Power Source

- Electric

- Weight

- 2500 Kilograms (kg)

- Power(W)

- 75 Horsepower (HP)

- Color

- White and Blue

- Power Consumption

- 220/440 Volt-Ampere (VA)

- Width

- 7.5 Foot (ft)

- Length

- 7 Foot (ft)

- Dimension (L*W*H)

- 7*7.5*15 Foot (ft)

600 MM DIA LLDPE Pulverizer Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About 600 MM DIA LLDPE Pulverizer Machine

The Plastic Pulverizer Machine (Disc Mill Type) is expertlyengineered to efficiently process PVC and LLDPE materials into fine,consistent powder. Its precision disc-based grinding system is ideal forproducing high-quality material essential for rotational molding, masterbatch,and other specialized applications.

High-Performance Design for Commercial Use

Constructed with mild steel, this machine delivers exceptional durability, longevity, and performance necessary for large-scale plastic pulverizing jobs in industrial settings. Its powerful 75 HP motor and expansive 600 mm grinding diameter streamline production and ensure consistent particle sizes.

Efficient Operation and Easy Integration

With dual voltage compatibility (220/440 VA) and electric power source, the machine can be seamlessly integrated into existing electrical setups. Its dimensions and robust weight minimize operational vibration, ensuring safety and reliability during use.

FAQs of 600 MM DIA LLDPE Pulverizer Machine:

Q: How does the 600 MM DIA LLDPE Pulverizer Machine operate?

A: This pulverizer works by feeding LLDPE and similar polymers into its 600 mm diameter grinding chamber, where high-speed rotating blades finely pulverize materials to the desired size. The electric motor, rated at 75 HP, provides ample power for continuous commercial operation.Q: What materials can be processed with this machine?

A: Primarily designed for LLDPE (Linear Low Density Polyethylene), this machine can also handle a wide range of similar thermoplastic polymers, delivering uniform fine powder suitable for roto-moulding and compounding applications.Q: When is the ideal time to use this pulverizer in manufacturing?

A: This machine is best utilized during the material preparation phase of plastic manufacturing, especially before processes like extrusion or moulding, to ensure optimal particle size and consistency for end-products.Q: Where can this pulverizer machine be installed?

A: Its commercial-grade construction suits large-scale industrial setups such as plastic processing plants, manufacturing units, and recycling centers across India. The machines substantial size requires placement in a spacious operating area.Q: What is the process of operating and maintaining the machine?

A: Operators should load materials, adjust settings for desired particle sizes, and ensure proper electrical connections. Routine maintenance involves cleaning the grinding chamber, inspecting the blades for wear, and checking electrical components for safety and efficiency.Q: How does this machine benefit commercial operations?

A: The machine accelerates material preparation, enhancing production throughput and product uniformity. Its durable construction and efficient design reduce downtime and maintenance needs, making it a cost-effective investment for bulk processing.Q: What safety measures should be observed during use?

A: Always follow manufacturer instructions, ensure proper grounding, keep the area clear of obstructions, and use safety gear such as gloves and goggles to prevent accidents when operating or maintaining the pulverizer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

Lldpe Pulverizer Disc Blade

Price 581000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Product Type : INDUSTRIAL PULVERISER MACHINE

Color : Blue & Ivory

Size : 300 MM 600 MM

Lldpe Plastic Pulverizer Machine

Price 471000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Product Type : INDUSTRIAL PULVERISER MACHINE

Color : WHITE & BLUE

Size : 300 MM 600 MM DISC

Lldpe Pulverizer Machine

Price 571000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Product Type : INDUSTRIAL PULVERISER MACHINE

Color : White and Blue

Size : 300 MM 600 MM DISC

Plastic Pulverizer Lldpe Machine

Price 551000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Product Type : INDUSTRIAL LLDPE PULVERISER MACHINE

Color : White

Size : 450 MM

Send Inquiry

Send Inquiry