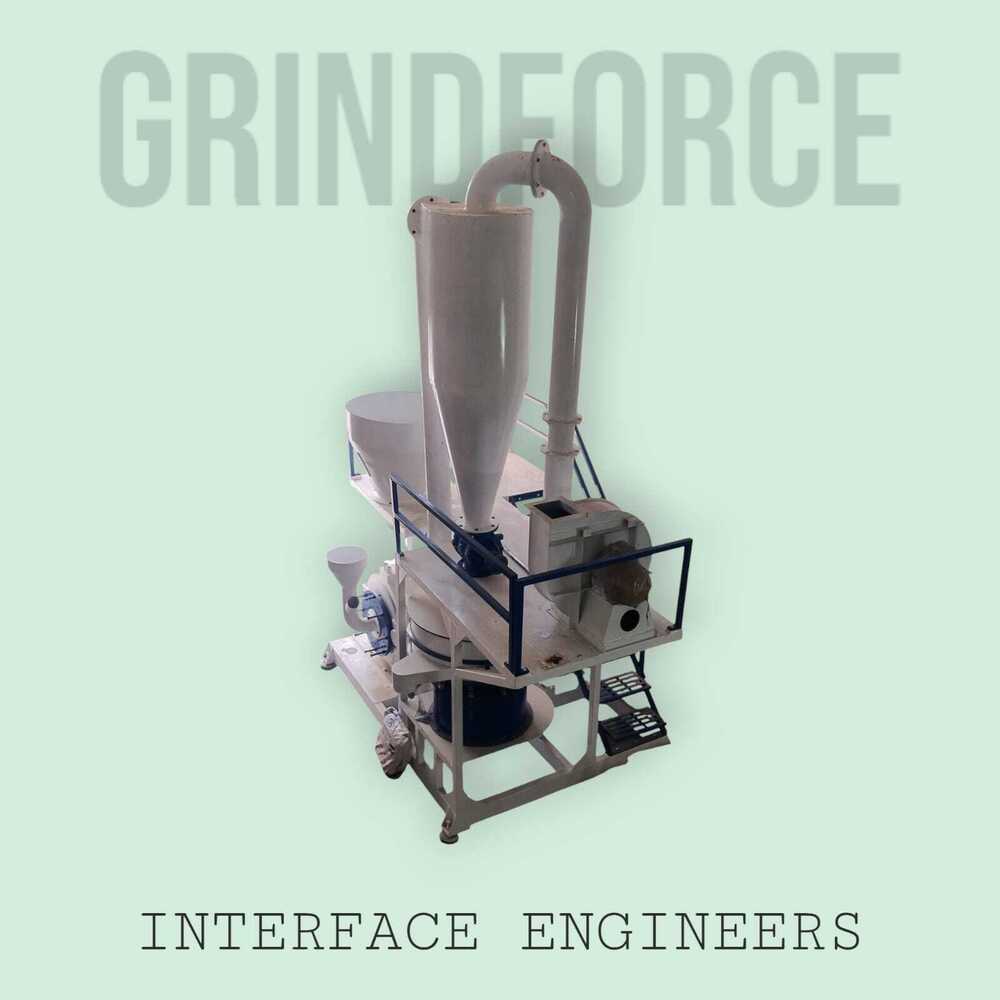

Lldpe Plastic Pulverizer Machine

Price 381000 INR/ Piece

Lldpe Plastic Pulverizer Machine Specification

- Usage

- Commercial

- Condition

- New

- Material

- Mild Steel

- Size

- 300 MM

- Height

- 11.5 Foot (ft)

- Power Source

- Electric

- Product Type

- INDUSTRIAL LLDPE PULVERISER MACHINE

- Power(W)

- 30 Horsepower (HP)

- Weight

- 1500 Kilograms (kg)

- Power Consumption

- 220/440 Volt-Ampere (VA)

- Color

- White and Blue

- Width

- 5.5 Foot (ft)

- Length

- 5.5 Foot (ft)

- Dimension (L*W*H)

- 11.5*5.5*5.5 Foot (ft)

Lldpe Plastic Pulverizer Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Lldpe Plastic Pulverizer Machine

The Plastic Pulverizer Machine (Disc Mill Type) is expertlyengineered to efficiently process PVC and LLDPE materials into fine,consistent powder. Its precision disc-based grinding system is ideal forproducing high-quality material essential for rotational molding, masterbatch,and other specialized applications.

Advanced Performance for Commercial Applications

Designed specifically for industrial environments, this LLDPE Plastic Pulverizer excels in grinding and processing plastic materials efficiently. Its 30 HP power and electric operation ensure continuous, heavy-duty usage, making it ideal for large-scale commercial operations. Its precise engineering delivers consistent results, enhancing productivity for manufacturers, traders, and suppliers alike.

Built for Durability and Versatility

Constructed from high-quality mild steel, the machine combines structural strength with resistance to wear. The sizable dimensions, accompanied by a solid 1500 kg weight, contribute to its stability during operation. Suitable for pulverizing a broad range of plastic articles, it supports a variety of industrial processes and is reliable for long-term use.

FAQs of Lldpe Plastic Pulverizer Machine:

Q: How do I install the LLDPE Plastic Pulverizer Machine at my facility?

A: Installation requires a level, stable floor space matching the machines dimensions (11.5 x 5.5 x 5.5 ft). Ensure a power source matching 220/440 VA specifications is available. Professional guidance from an authorized technician or service provider is recommended for safe setup.Q: What types of plastic materials can this pulverizer process?

A: The machine is designed to efficiently pulverize LLDPE and other compatible plastic materials, making it suitable for recycling, reprocessing, and manufacturing industries.Q: When should I perform maintenance on the LLDPE Plastic Pulverizer Machine?

A: Regular maintenance intervals depend on usage intensity, but it is advisable to inspect and service the machine at least quarterly to maintain optimal performance and machine longevity.Q: Where can I purchase the machine or spare parts in India?

A: You can acquire this machine or authorized spare parts from leading distributors, exporters, suppliers, and manufacturers across India. Many traders and wholesalers also provide after-sales support.Q: What is the operating process of the plastic pulverizer?

A: Feed plastic materials into the entry section, where the robust blades powered by a 30 HP electric motor pulverize materials to the desired size. The processed plastic exits through the output section, ready for further production or recycling.Q: How is the machine beneficial for my business operations?

A: This pulverizer increases efficiency by delivering consistent plastic powder output, minimizes downtime with its durable structure, and enhances productivity for commercial-scale plastic processing.Q: What are the safety considerations when using this equipment?

A: Operators should follow the safety instructions provided, wear proper protective gear, and ensure all safety guards are in place during operation. Only trained staff should operate and maintain the machine.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

Lldpe Pulverizer Disc Blade

Price 581000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Size : 300 MM 600 MM

Weight : 1500 Kilograms (kg)

Power(W) : 40 Horsepower (HP)

Masterbatch Plastic Pulverizer

Price 580000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Size : 300 MM 600 MM DISC

Weight : 1500 Kilograms (kg)

Power(W) : 40 Horsepower (HP)

Plastic Pulverizer Lldpe Machine

Price 551000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Size : 450 MM

Weight : 1700 Kilograms (kg)

Power(W) : 25 Horsepower (HP)

600 MM DIA LLDPE Pulverizer Machine

Price 841000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Size : 600 MM

Weight : 2500 Kilograms (kg)

Power(W) : 75 Horsepower (HP)

Send Inquiry

Send Inquiry