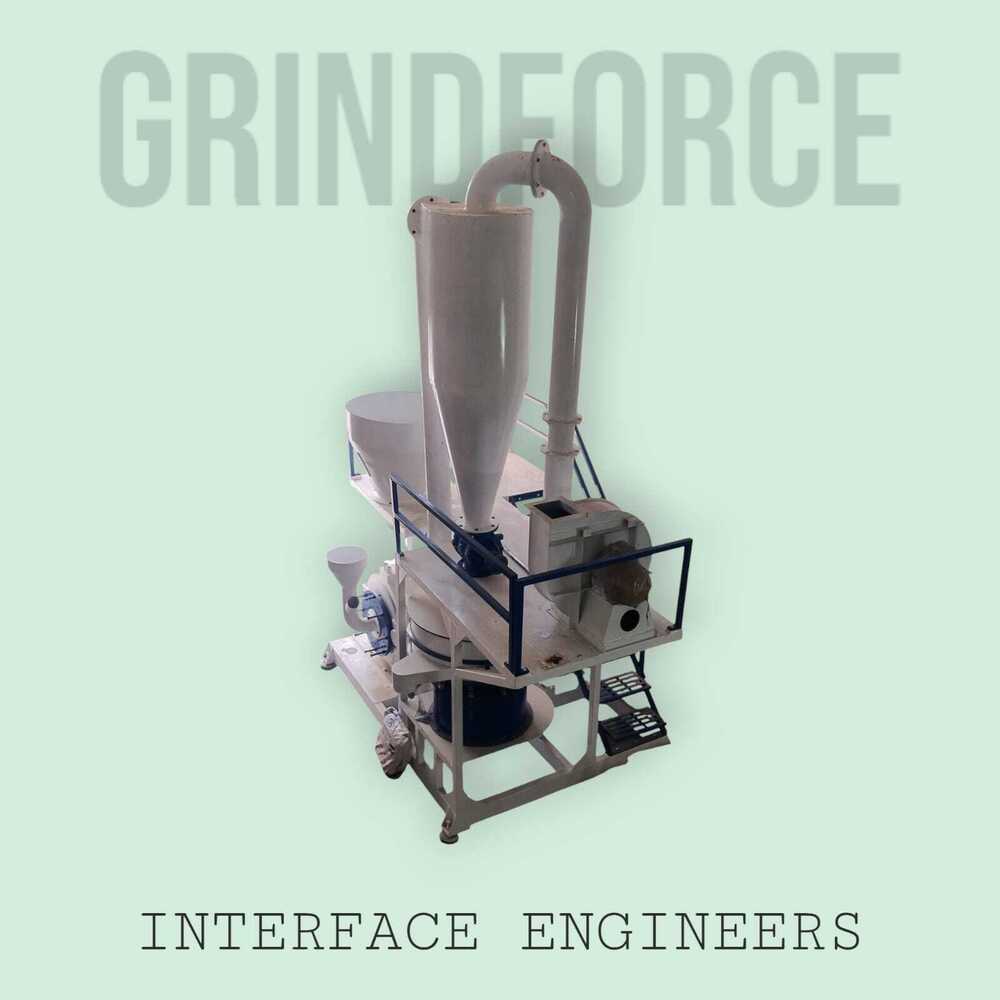

LLDPE Plastic Pulverizer Machine Manufacturer

Price 550000 INR/ Piece

LLDPE Plastic Pulverizer Machine Manufacturer Specification

- Usage

- Commercial

- Condition

- New

- Material

- Mild Steel

- Size

- 300 MM - 600 MM

- Height

- 11.5 Foot (ft)

- Power Source

- Electric

- Product Type

- INDUSTRIAL PULVERISER MACHINE

- Weight

- 1800 Kilograms (kg)

- Power(W)

- 50 Horsepower (HP)

- Power Consumption

- 40 Horsepower (HP)

- Color

- White and Blue

- Width

- 6 Foot (ft)

- Length

- 5.5 Foot (ft)

- Dimension (L*W*H)

- 6FT * 5.5 FT * 15 FT Foot (ft)

LLDPE Plastic Pulverizer Machine Manufacturer Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About LLDPE Plastic Pulverizer Machine Manufacturer

For efficient and consistent powdering of PVC andLLDPE materials, our Disc Mill Plastic Pulverizer is the ideal solution.1 Its advanced disc technology ensures optimal particledistribution and high throughput, making it indispensable for industriesrelying on finely processed PVC and LLDPE.

Efficient Material Reduction

Engineered for commercial use, this LLDPE Plastic Pulverizer Machine efficiently grinds plastic materials, turning them into fine powder suitable for recycling and compound manufacturing. The 50 HP motor ensures rapid operation, while the machines stability and build provide consistent results over prolonged industrial usage.

Robust Construction and Design

Manufactured from high-grade mild steel, the machine guarantees durability and longevity even under rigorous workflows. Its spacious chamber and adaptable size range (300 MM to 600 MM) allow for high throughput, optimizing productivity for businesses in the plastic processing sector.

Versatile Commercial Applications

Serving as a key equipment for distributors, exporters, and wholesalers, this pulverizer caters to various commercial needs, including recycling plants, polymer processors, and custom compounding units throughout India. Its adaptability enhances efficiency across a spectrum of material handling scenarios.

FAQs of LLDPE Plastic Pulverizer Machine Manufacturer:

Q: How does the LLDPE Plastic Pulverizer Machine operate?

A: This machine utilizes a powerful 50 HP electric motor to rotate grinders that pulverize LLDPE plastic into fine powder. Operated via an electric power source, it provides uniform particle size for downstream applications.Q: What materials and sizes can the pulverizer process?

A: The pulverizer is specifically engineered for commercial-grade LLDPE and other plastic materials, accepting input sizes between 300 MM and 600 MM, making it versatile for various processing requirements.Q: When should I consider using this machine in my production facility?

A: This pulverizer is ideal whenever you need efficient size reduction of plastic waste or raw materials for recycling, compound blending, or downstream manufacturing activities.Q: Where is the LLDPE Plastic Pulverizer most commonly used?

A: The machine finds its primary use in plastic recycling plants, polymer processing factories, and commercial compounding units across distribution and manufacturing sectors in India.Q: What is the process for installing and commissioning this machine?

A: Installation involves positioning the machine in a suitable facility space (6FT x 5.5FT x 15FT) with access to an electric power supply. Professional setup ensures optimal operation and safety inspections before use.Q: What are the key benefits of using this pulverizer machine?

A: Key advantages include efficient material throughput, consistency in output quality, durable mild steel construction, and suitability for high-volume commercial operations. It aids in streamlining recycling and production processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

Lldpe Plastic Pulverizer Machine

Price 471000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 2000 Kilograms (kg)

Power Consumption : 220/440 VoltAmpere (VA)

Width : 6 Foot (ft)

Material : Mild Steel

Plastic Scrap Pulverizer

Price 451000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1500 Kilograms (kg)

Power Consumption : 220/440 VoltAmpere (VA)

Width : 6 Foot (ft)

Material : Mild Steel

Lldpe Pulverizer Disc Blade

Price 581000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1500 Kilograms (kg)

Power Consumption : 220/440 VoltAmpere (VA)

Width : 6 Foot (ft)

Material : Mild Steel

LLDPE Granuel Pulverizer Machine

Price 421000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1850 Kilograms (kg)

Power Consumption : 220/440 VoltAmpere (VA)

Width : 5.5 Foot (ft)

Material : Mild Steel

Send Inquiry

Send Inquiry