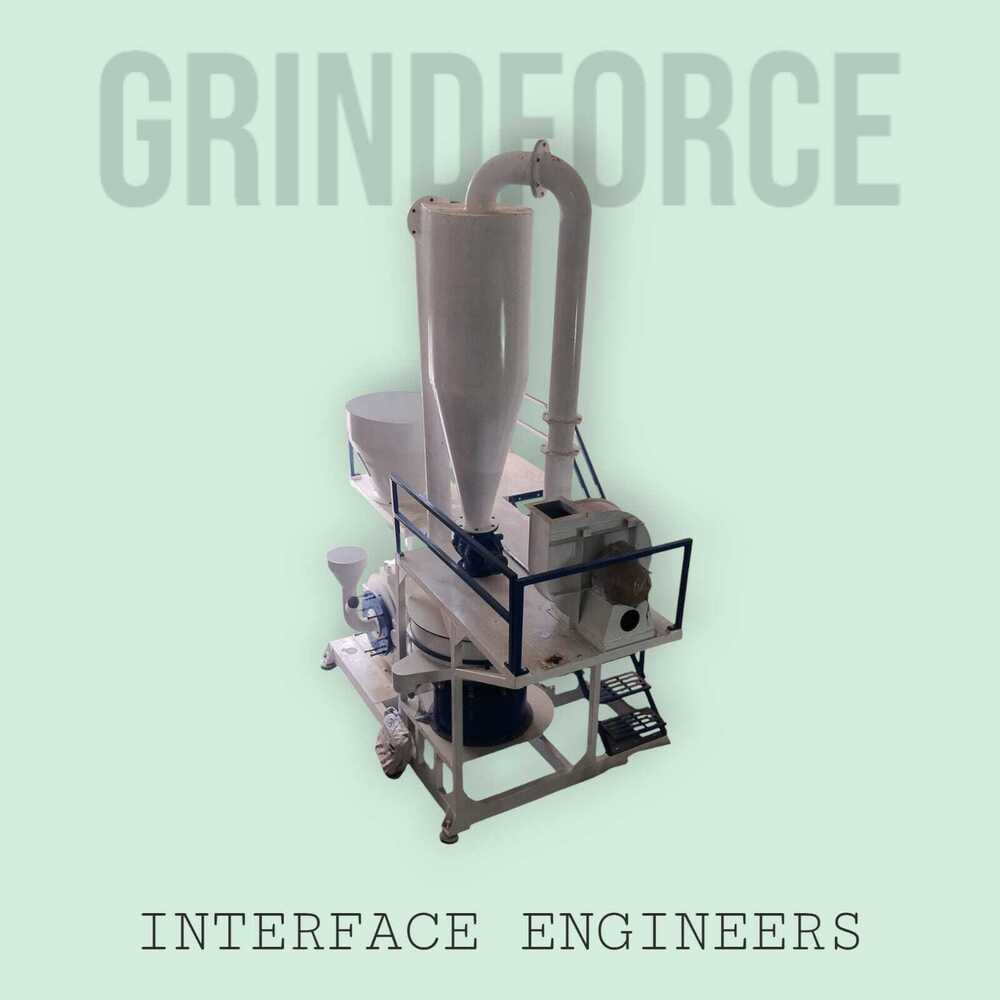

Lldpe Plastic Pulverizer Machine

Price 571000 INR/ Piece

Lldpe Plastic Pulverizer Machine Specification

- Usage

- Industrial

- Height

- 11.5 Foot (ft)

- Width

- 6 Foot (ft)

- Length

- 5.5 Foot (ft)

- Product Type

- INDUSTRIAL PULVERISER MACHINE

- Weight

- 1800 Kilograms (kg)

- Size

- 300 MM - 600 MM DISC

- Color

- White and Blue

- Condition

- New

- Material

- Mild Steel

- Power Source

- Electric

- Power(W)

- 40 Horsepower (HP)

- Power Consumption

- 220/440 Volt-Ampere (VA)

- Dimension (L*W*H)

- 11.5*5.5*5.5 Foot (ft)

Lldpe Plastic Pulverizer Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Lldpe Plastic Pulverizer Machine

The Plastic Pulverizer Machine (Disc Mill Type) is expertlyengineered to efficiently process PVC and LLDPE materials into fine,consistent powder. Its precision disc-based grinding system is ideal forproducing high-quality material essential for rotational molding, masterbatch,and other specialized applications.

Efficient Pulverizing for Industrial Plastics

The LLDPE Plastic Pulverizer Machine streamlines the grinding and pulverizing of plastics such as LLDPE, offering industries a dependable solution for recycling processes. With an impressive 40 HP power output, it can handle large volumes efficiently, making it an optimal choice for workshops, factories, and recycling units.

Robust Construction and Versatile Design

Manufactured from high-grade mild steel, this machine is engineered for long-term use and minimal maintenance. Its adjustable disc sizes (300 MM 600 MM) cater to a variety of plastic processing requirements, while the compact footprint ensures it fits seamlessly in diverse industrial environments throughout India.

FAQs of Lldpe Plastic Pulverizer Machine:

Q: How does the LLDPE Plastic Pulverizer Machine operate?

A: The machine operates using a powerful 40 horsepower electric motor, which drives high-speed rotating discs to pulverize plastic materials such as LLDPE. Users feed raw plastic into the hopper, and the machine pulverizes it into fine powder suitable for further processing or recycling.Q: What applications are suitable for this pulverizer machine?

A: This machine is designed for industrial usage, particularly in plastic recycling plants, manufacturing units, and workshops that deal with LLDPE or similar plastics. It is widely used for grinding, powdering, and reprocessing plastic materials for reuse.Q: When should the machine be maintained?

A: Routine maintenance, including inspection and cleaning, should be performed after every operational cycle or as specified by the manufacturer. Regular checks help in prolonging the lifespan of the machine and ensure efficient performance.Q: Where can the LLDPE Plastic Pulverizer Machine be installed?

A: With its dimensions of 11.5 x 5.5 x 5.5 feet and robust construction, the machine can be installed in factories, large workshops, or dedicated recycling facilities that have the necessary floor space and an adequate electrical supply.Q: What is the process for pulverizing plastics with this machine?

A: Raw plastic material is loaded into the feeding system, where the rotating discs fragment it into smaller particles. The ground material exits through a designated outlet, ready for collection. The entire process is continuous, supporting efficient high-volume production.Q: How does using this pulverizer machine benefit industrial operations?

A: Utilizing this pulverizer enhances material recycling rates, reduces plastic waste, and delivers consistent output. Its efficient electric motor and sturdy design lead to lower downtime and fresher powder, ensuring higher product quality and cost savings for businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

LLDPE Plastic Pulverizer Machine Manufacturer

Price 550000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Commercial

Height : 11.5 Foot (ft)

Width : 6 Foot (ft)

Dimension (L*W*H) : 6FT * 5.5 FT * 15 FT Foot (ft)

Lldpe Plastic Pulverizer Machine

Price 471000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Height : 11.5 Foot (ft)

Width : 6 Foot (ft)

Dimension (L*W*H) : 11.5*5.5*5.5 Foot (ft)

Lldpe Plastic Pulverizer Machine

Price 381000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Commercial

Height : 11.5 Foot (ft)

Width : 5.5 Foot (ft)

Dimension (L*W*H) : 11.5*5.5*5.5 Foot (ft)

Plastic Scrap Pulverizer

Price 451000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Height : 11.5 Foot (ft)

Width : 6 Foot (ft)

Dimension (L*W*H) : 6FT * 5.5 FT * 15 FT Foot (ft)

Send Inquiry

Send Inquiry