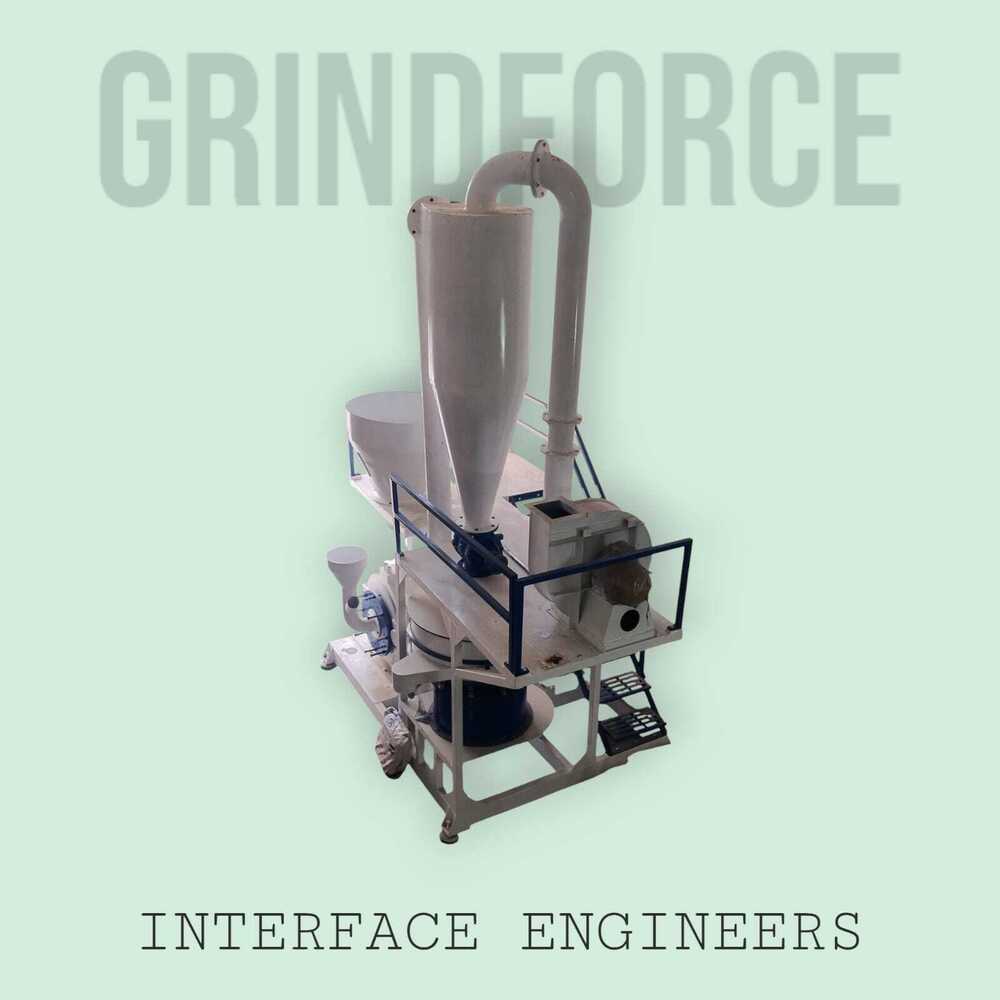

Disc Type Pulverizer FOR LLDPE & PVC

Price 391000 INR/ Piece

Disc Type Pulverizer FOR LLDPE & PVC Specification

- Usage

- Commercial

- Condition

- New

- Material

- Mild Steel

- Size

- 300 MM - 600 MM

- Height

- 11.5 Foot (ft)

- Power Source

- Electric

- Product Type

- INDUSTRIAL LLDPE PULVERISER MACHINE

- Power(W)

- 40 Horsepower (HP)

- Weight

- 1500-2000 Kilograms (kg)

- Color

- White and Blue

- Power Consumption

- 220/440 Volt-Ampere (VA)

- Width

- 7.5 Foot (ft)

- Length

- 7 Foot (ft)

- Dimension (L*W*H)

- 7*7.5*11 Foot (ft)

Disc Type Pulverizer FOR LLDPE & PVC Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Disc Type Pulverizer FOR LLDPE & PVC

The Plastic Pulverizer Machine (Disc Mill Type) is expertlyengineered to efficiently process PVC and LLDPE materials into fine,consistent powder. Its precision disc-based grinding system is ideal forproducing high-quality material essential for rotational molding, masterbatch,and other specialized applications.

Efficient Pulverization for Plastics

This disc type pulverizer offers powerful and precise grinding for LLDPE and PVC materials, making it ideal for large-scale production needs. With its 40 HP electric motor and robust mild steel body, you are assured of consistent performance, reduced material waste, and easy maintenance, supporting high-output operations for various industry participants.

Versatile Usage Across Industries

Designed for commercial applications, this pulverizer can be integrated seamlessly into plastic manufacturing, recycling, or processing plants. Its compatibility with materials sized between 300 mm and 600 mm ensures that it caters to a wide range of operational requirements, supporting the dynamic needs of Indian businesses.

FAQs of Disc Type Pulverizer FOR LLDPE & PVC:

Q: How does the disc type pulverizer enhance the processing of LLDPE and PVC materials?

A: The pulverizer utilizes high-speed rotating discs to finely grind LLDPE and PVC, ensuring uniform particle sizes for efficient downstream application. Its robust power output guarantees high throughput and consistent quality in commercial plastic processing.Q: What safety and operational benefits does the machine provide?

A: Constructed from mild steel and supported by a heavy-duty frame, the pulverizer is stable during operation. It features electric power supply compatibility (220/440 VA), color-coded safety features, and a user-friendly interface, thereby reducing operator fatigue and risk of accidents.Q: When is the ideal time to use this pulverizer in the production process?

A: Deploy the pulverizer after preliminary material shredding but before extrusion or molding processes. It ensures that materials achieve the required fineness for effective melting and molding, thus optimizing the overall manufacturing workflow.Q: Where can this equipment be installed for best results?

A: Due to its dimensions (7*7.5*11 ft) and robust structure, the pulverizer should be set up in a well-ventilated, accessible area within commercial manufacturing or recycling facilities that can support its weight and electrical requirements.Q: What is the process for operating the Disc Type Pulverizer?

A: Operators load pre-treated plastics into the feed hopper, set the desired disc spacing for particle size, and initiate the electric motor. The machine provides continuous pulverization, with ground material collected below for further processing or packaging.Q: What are the main advantages of choosing this pulverizer for your business?

A: It offers reliable, large-volume grinding suitable for commercial operations, high energy efficiency, and a durable mild steel construction. The versatile size range and straightforward maintenance make it a valuable long-term investment for manufacturers, exporters, and other stakeholders in the plastics industry.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LLDPE Pulverizer Machine Category

Lldpe Pulverizer Disc Blade

Price 581000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1500 Kilograms (kg)

Size : 300 MM 600 MM

Product Type : INDUSTRIAL PULVERISER MACHINE

Usage : Industrial

Masterbatch Plastic Pulverizer

Price 580000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1500 Kilograms (kg)

Size : 300 MM 600 MM DISC

Product Type : INDUSTRIAL PULVERISER MACHINE

Usage : Industrial

Lldpe Plastic Pulverizer Machine

Price 381000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1500 Kilograms (kg)

Size : 300 MM

Product Type : INDUSTRIAL LLDPE PULVERISER MACHINE

Usage : Commercial

Lldpe Plastic Pulverizer Machine

Price 471000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 2000 Kilograms (kg)

Size : 300 MM 600 MM DISC

Product Type : INDUSTRIAL PULVERISER MACHINE

Usage : Industrial

Send Inquiry

Send Inquiry