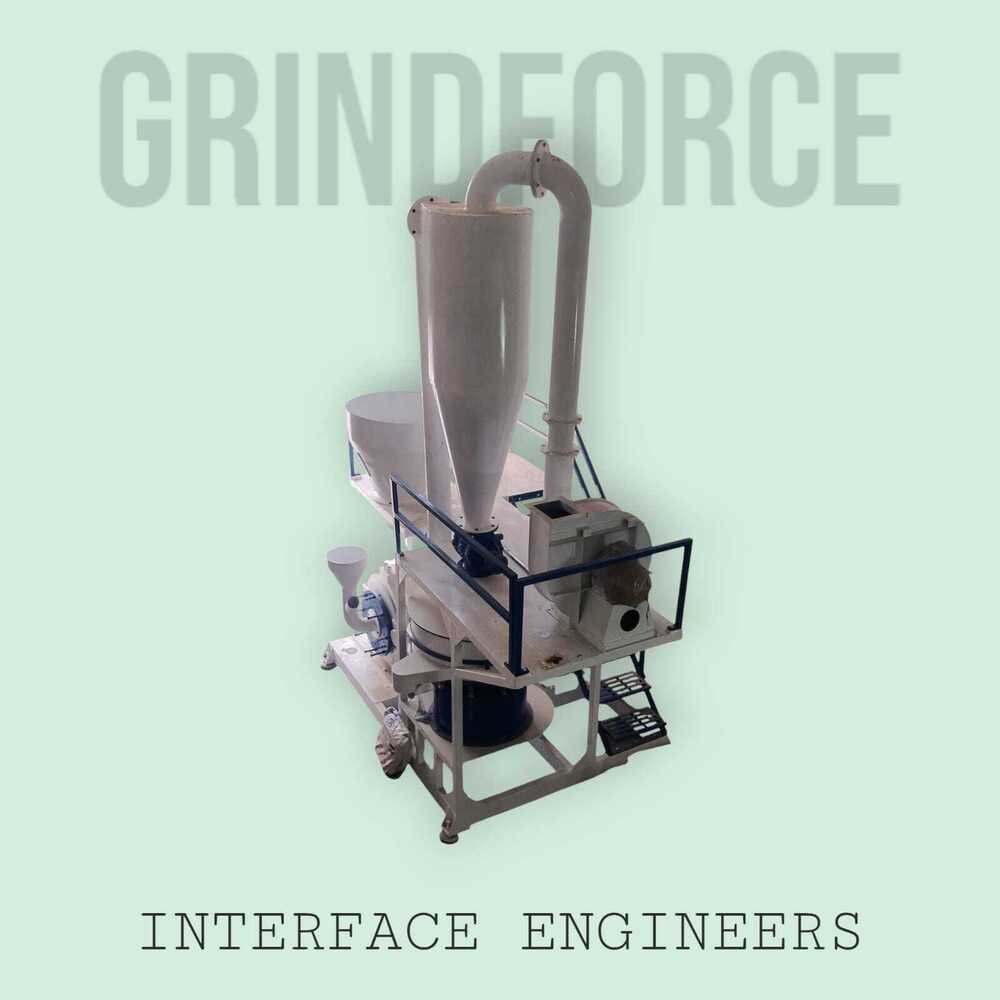

Pvc Scrap Pulverizer

Price 651000 INR/ Piece

Pvc Scrap Pulverizer Specification

- Usage

- INDUSTRIAL

- Condition

- New

- Size

- 300 MM - 600 MM DISC

- Material

- Mild Steel

- Height

- 15 Foot (ft)

- Product Type

- INDUSTRIAL PVC PULVERISER MACHINE

- Power Source

- Electric

- Weight

- 2000 Kilograms (kg)

- Power(W)

- 40 Horsepower (HP)

- Color

- White and Blue

- Power Consumption

- 220/440 Volt-Ampere (VA)

- Width

- 6 Foot (ft)

- Length

- 7 Foot (ft)

- Dimension (L*W*H)

- 7*6*15 Foot (ft)

Pvc Scrap Pulverizer Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Pvc Scrap Pulverizer

The Plastic Pulverizer Machine (Disc Mill Type) is expertlyengineered to efficiently process PVC and LLDPE materials into fine,consistent powder. Its precision disc-based grinding system is ideal forproducing high-quality material essential for rotational molding, masterbatch,and other specialized applications.

High-Performance PVC Pulverization

Designed specifically for industrial use, the PVC Scrap Pulverizer efficiently converts scrap PVC into fine powder suitable for recycling and further processing. Its solid 40 HP electric motor ensures steady, reliable operation, handling large volumes of material with minimal maintenance. The machines dimensions and weight contribute to its stability, while the use of mild steel ensures longevity.

Versatility and Industrial Application

With a disc size adaptable between 300 and 600 mm, this pulverizer accommodates different processing capacities. Ideal for manufacturers, suppliers, and service providers, the machine is well-suited for use in recycling plants, plastic manufacturing, and waste management facilities. Its electric configuration guarantees consistent output, making it a valuable addition to any industrial setup.

FAQs of Pvc Scrap Pulverizer:

Q: How is the PVC Scrap Pulverizer operated in an industrial setting?

A: The PVC Scrap Pulverizer operates using a robust 40 HP electric motor, compatible with standard 220 or 440 VA power supplies. Once connected and properly set up, scrap PVC is fed into the machine, which pulverizes the material into fine powder suitable for recycling or reuse.Q: What are the main benefits of using this PVC Scrap Pulverizer?

A: This pulverizer enhances recycling efficiency by converting PVC scrap into reusable fine powder, reducing waste and production costs. Its sturdy construction and powerful electric motor ensure long-lasting performance and minimal downtime in industrial environments.Q: When should the pulverizer be used for optimal results?

A: For optimal results, the pulverizer should be used when large quantities of PVC scrap require consistent and uniform size reduction. Its efficient design handles continuous operation, making it ideal for high-volume industrial applications.Q: Where can this pulverizer be installed and used?

A: This machine is intended for installation in industrial facilities such as recycling plants, plastic manufacturing units, or waste management systems. With its durable design and significant footprint, it is suitable for use in well-ventilated, stable environments with adequate power supply.Q: What is the process for pulverizing PVC scrap using this machine?

A: The process involves loading PVC scrap into the input section, where rotating discs (300 to 600 mm) grind the material under high power. The pulverized powder is then collected for further industrial processing or recycling.Q: Why choose a mild steel construction for the PVC Pulverizer?

A: Mild steel is chosen for its strength, resistance to wear, and ability to withstand heavy-duty industrial operation, making it an ideal material for high-impact machinery like the PVC Scrap Pulverizer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Pulverizer Machine Category

Upvc Pulverizer Machine With Dust Collector

Price 591000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Usage : Industrial

Power Source : Electric

Power(W) : 47 Horsepower (HP)

Pvc Thread Pulverizer Machine

Price 601000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Usage : Industrial

Power Source : Electric

Power(W) : 40 Horsepower (HP)

Plastic Scrap Pulverizer Manufacturer In India

Price 750000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Usage : Commercial

Power Source : Electric

Power(W) : 220440 Volt (v)

Pvc Pulverizer Manufacturers In India

Price 611000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Usage : Commercial

Power Source : Electric

Power(W) : 40 Horsepower (HP)

Send Inquiry

Send Inquiry