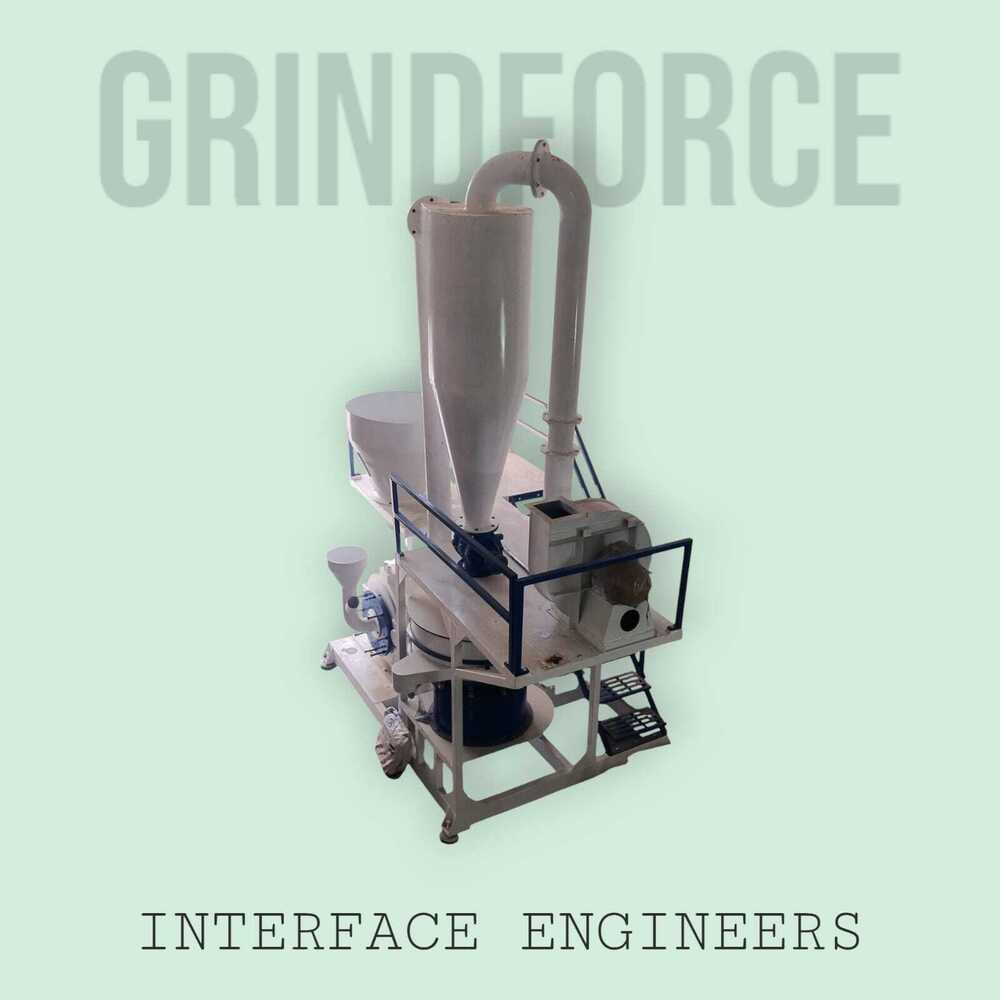

Pvc Pulverizer Manufacturers In India

Price 611000 INR/ Piece

Pvc Pulverizer Manufacturers In India Specification

- Usage

- Commercial

- Condition

- New

- Material

- Mild Steel

- Size

- 80 KG/HR -500 KG/HR

- Product Type

- INDUSTRIAL PULVERISER MACHINE

- Power Source

- Electric

- Power(W)

- 40 Horsepower (HP)

- Weight

- 1800 Kilograms (kg)

- Power Consumption

- 20-150 HP Horsepower (HP)

- Color

- White & BLUE

- Dimension (L*W*H)

- 6FT * 5.5 FT * 15 FT Foot (ft)

Pvc Pulverizer Manufacturers In India Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 5 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- WOODEN PALLET / WOODEN BOX PACKAGING TO ENSURE PRODUCT SAFETY.

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Pvc Pulverizer Manufacturers In India

Utilizing a high-speedrotating disc or mill, it excels in processing thermoplastic and somethermosetting polymers, making them ideal for subsequent manufacturingprocesses such as rotational molding, compounding, masterbatch production, andcoating applications.

Here's a description for a pulverizer machineused in various plastic materials, focusing on its function of grinding intofine powder:

Key Features &Applications:

· Specificallydesigned to handle an extensive array of plastic types, including but notlimited to:

o Essentialfor applications requiring excellent flowability and consistent particle sizefor rotational molding.

o o Crucial for pipe, profile, and cablemanufacturing, enabling precise formulation and enhanced material properties.

o Grinding for specialized rigidapplications where fine powder is paramount for uniform blending.

o Preparingmaterial for high-temperature and corrosive environment applications.

o Engineered to deliver a consistent and customizableparticle size, ranging from coarse granules to ultra-fine powders (typically 20to 100 mesh or finer), ensuring optimal material flow and dispersion indownstream processes.

o o Built withwear-resistant components, often utilizing hardened steel or specializedalloys, to withstand the abrasive nature of various plastic materials andensure long operational life.

o Advanced Cooling Systems: Incorporates efficient coolingmechanisms (e.g., water-cooled jackets, air cooling) to prevent heat buildupduring the grinding process, preserving the material's properties andpreventing degradation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Pulverizer Machine Category

Pvc Scrap Pulverizer

Price 651000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 2000 Kilograms (kg)

Material : Mild Steel

Power(W) : 40 Horsepower (HP)

Usage : INDUSTRIAL

Natural Reprocess Pvc Pulverizer Machine

Price 561000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1750 Kilograms (kg)

Material : Mild Steel

Power(W) : 50 Horsepower (HP)

Usage : Industrial

RPVC ( Process) Pulverizer, For Industries

Price 711000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 18502200 Kilograms (kg)

Material : Mild Steel

Power(W) : 50 Horsepower (HP)

Usage : Commercial

Pvc Scrap Pulverizer Machine

Price 651000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1500 3000 KG Kilograms (kg)

Material : Mild Steel

Power(W) : 220/440 Volt (v)

Usage : Commercial

Send Inquiry

Send Inquiry