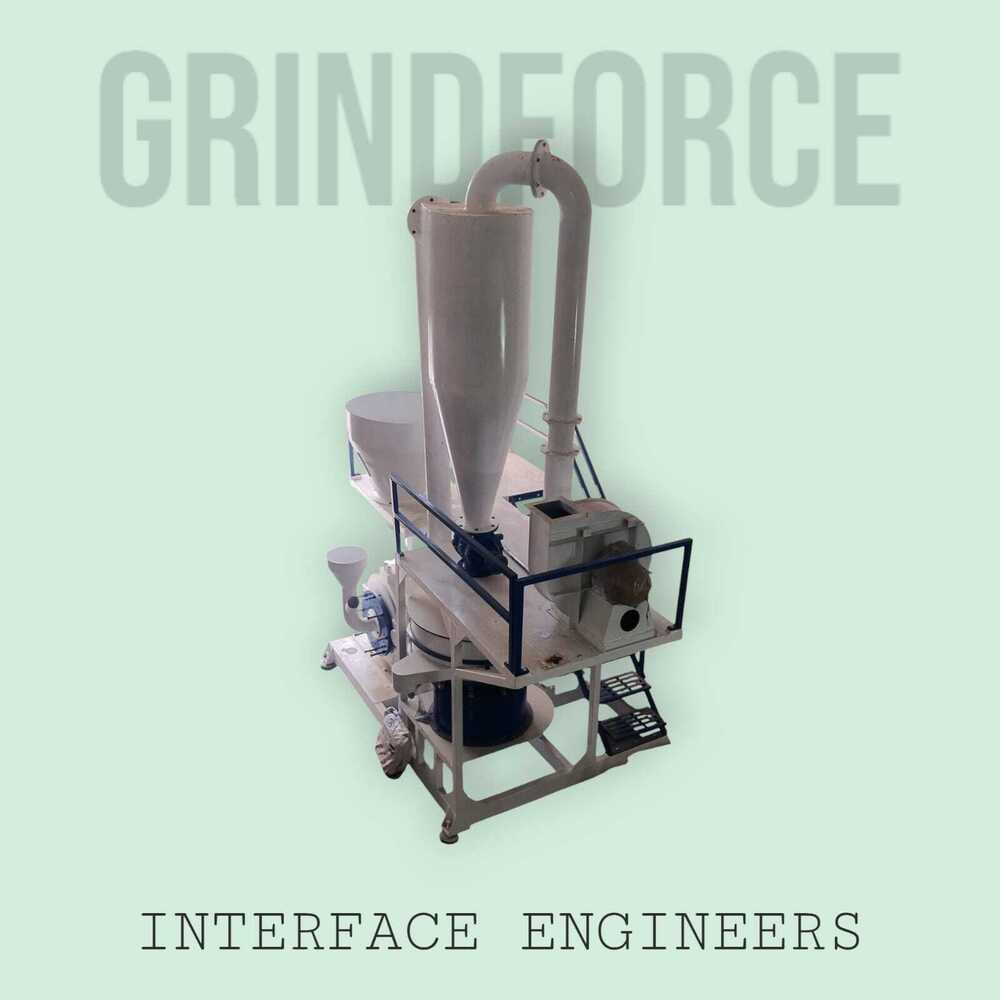

Natrul Pvc Regring Pulverizer Machine In Gujrat

Price 551000 INR/ Piece

Natrul Pvc Regring Pulverizer Machine In Gujrat Specification

- Usage

- Industrial

- Condition

- New

- Material

- Mild Steel

- Power Source

- Electric

- Power(W)

- 58 Horsepower (HP)

- Weight

- 1900 Kilograms (kg)

- Power Consumption

- 50 Horsepower (HP)

- Color

- Gray & White

Natrul Pvc Regring Pulverizer Machine In Gujrat Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Natrul Pvc Regring Pulverizer Machine In Gujrat

Achieve micro-fine powders from PVC and LLDPE with thishigh-performance Disc Mill Plastic Pulverizer. Designed for robustoperation, it provides efficient and consistent size reduction, meeting the stringentrequirements for CPVC PIPE, UPVC PIPE, and WATER TANK MFG. applications usingthese polymers.

High-Performance PVC Regrinding

Designed with advanced engineering, this machine swiftly pulverizes PVC regrind into fine powder, enabling recycling and reuse. Its 58 HP electric power source ensures consistent performance while maintaining energy efficiency. Industrial-grade mild steel construction guarantees longevity even in demanding environments.

Versatile Applications for Industry

The Natrul PVC Regrind Pulverizer Machine serves a broad spectrum of users, including manufacturers, exporters, and suppliers across India. It is ideal for plastic recycling and materials recovery, supporting sustainability and operational efficiency for businesses of all sizes.

FAQs of Natrul Pvc Regring Pulverizer Machine In Gujrat:

Q: How does the Natrul PVC Regrind Pulverizer Machine operate?

A: The machine utilizes a 58 HP electric motor to pulverize PVC regrind, turning it into a fine powder suitable for reuse in manufacturing or recycling processes. Its robust design ensures smooth and reliable operation.Q: What materials can be processed with this pulverizer machine?

A: This machine is specifically engineered for PVC materials but can also handle related thermoplastics. Its construction from mild steel ensures durability when processing industrial regrinds.Q: When is it ideal to use this pulverizer in the production cycle?

A: The pulverizer is most effective after the initial collection and sorting of PVC scrap. It is used prior to remanufacturing steps, ensuring uniform powder for high-quality end products.Q: Where can the Natrul PVC Regrind Pulverizer Machine be installed?

A: It is suitable for installation in industrial facilities across India including recycling centers, manufacturing plants, or plastic processing workshops, thanks to its compact design and reliable power source.Q: What is the process for operating and maintaining the machine?

A: Operation involves feeding the PVC material into the hopper, where it is ground by high-speed rotating blades. Maintenance includes routine inspections, cleaning, and timely lubrication for peak performance.Q: How is this pulverizer machine beneficial for industrial users?

A: By efficiently recycling PVC waste, it helps reduce raw material costs, supports environmental sustainability, and boosts operational productivity with minimal energy consumption.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Pulverizer Machine Category

Pvc Scrap Pulverizer

Price 651000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Consumption : 220/440 VoltAmpere (VA)

Power Source : Electric

Material : Mild Steel

Power(W) : 40 Horsepower (HP)

Upvc Pulverizer Machine With Dust Collector

Price 591000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Consumption : 40 Horsepower (HP)

Power Source : Electric

Material : Mild Steel

Power(W) : 47 Horsepower (HP)

Pvc Pulverizer Machine With Dust Collector

Price 725000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Consumption : 40 Horsepower (HP)

Power Source : Electric

Material : Mild Steel

Power(W) : 50 Horsepower (HP)

Pvc Thread Pulverizer Machine

Price 601000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Consumption : 50 Horsepower (HP)

Power Source : Electric

Material : Mild Steel

Power(W) : 40 Horsepower (HP)

Send Inquiry

Send Inquiry