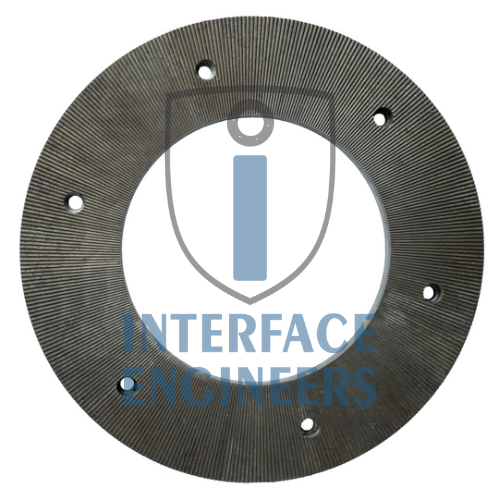

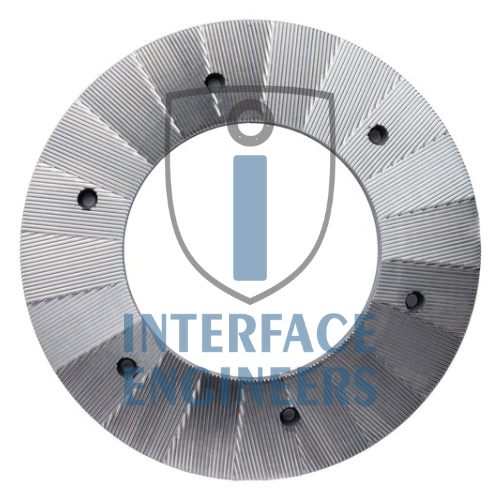

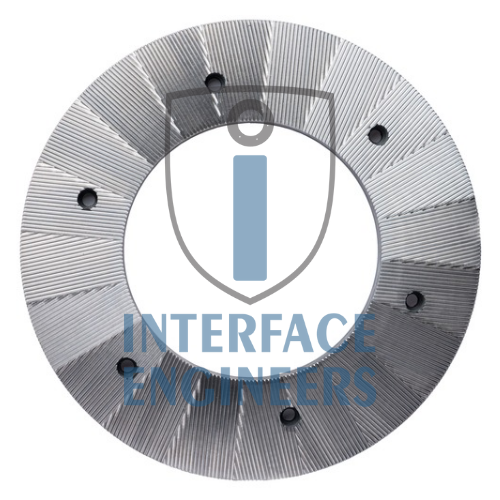

300 Mm Lldpe Pulverizer Disc Blade

Price 22000 INR/ Piece

300 Mm Lldpe Pulverizer Disc Blade Specification

- Shape

- Round

- Usage

- Commercial

- Size

- 600mm

- Product Type

- PULVERISER DISC BLADE

- Weight

- 20-75 KG Kilograms (kg)

- Color

- Grey

300 Mm Lldpe Pulverizer Disc Blade Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About 300 Mm Lldpe Pulverizer Disc Blade

DISCBLADE FOR PULVERISER MACHINE.

SUITABLE FOR FINE POWDER PRODUCTION

OUR DISC BLADE CAN EASILY INCREASEMINIMUN 15 KG PER HOUR PRODUCTION IN YOUR EXISTING MACHINE.

OUR DISC BLADE IS SUITABLE FOR MATERIAL LIKE:

PVC SCRAP

LLDPE

RPVC

CPVC

UPVC

NATURAL RUBBER

ETC...

WE CAN SUPPLY OUR PRODUCT GLOBALLY. CURRENTNOTWORK OF BUSINESS IS INDIA , NEPAL , BHUTAN, AND CONTINUOUSLY EXPANDING.

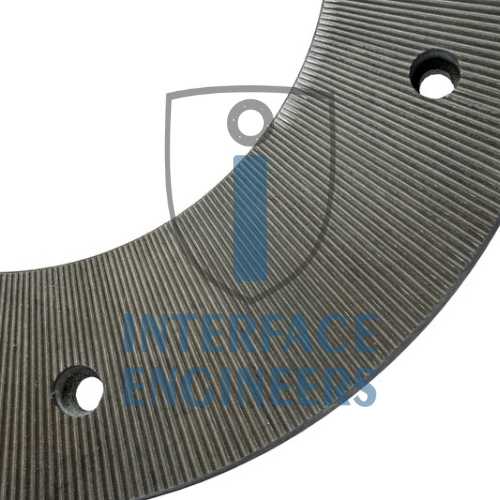

High-Quality Die Steel Construction

Engineered from robust die steel, the 300 Mm LLDPE Pulverizer Disc Blade is designed for extended service life and reliable performance in demanding commercial environments. Die steel enhances the blades resistance to wear and deformation, making it a top choice for consistent pulverizing efficiency.

Versatile Commercial Applications

This pulverizer disc blade supports a broad range of industries, including manufacturing, recycling, and material processing. Its manual operation ensures easy integration with existing machinery, making it suitable for both large-scale operations and specialized small businesses.

FAQs of 300 Mm Lldpe Pulverizer Disc Blade:

Q: How is the 300 Mm LLDPE Pulverizer Disc Blade used in commercial settings?

A: The disc blade is installed in pulverizer machines for grinding and pulverizing LLDPE and similar materials. Its robust design makes it suitable for high-volume operations in commercial and industrial environments.Q: What materials are used in the manufacturing of this disc blade?

A: The blade is manufactured from premium die steel, which offers superior hardness, wear resistance, and longevity, even under demanding operating conditions.Q: When should I replace the pulverizer disc blade?

A: Blade replacement is recommended when there is a noticeable decrease in pulverizing efficiency, visible wear, or chipping along the blades edges. Regular maintenance checks will help determine the optimal replacement interval.Q: Where can I source this disc blade within India?

A: You can obtain the 300 Mm LLDPE Pulverizer Disc Blade from authorized distributors, exporters, importers, manufacturers, suppliers, traders, wholesalers, and service providers throughout India.Q: What is the process for installing the disc blade?

A: Installation typically involves securing the round disc onto the pulverizers spindle using compatible fasteners, followed by alignment and adjustment according to the machine manufacturers guidelines for optimal performance.Q: How does the manual power source benefit operators?

A: The manual operation allows users to maintain greater control over the pulverizing process, making it especially beneficial for customized or lower-scale production needs.Q: What are the primary benefits of using this die steel disc blade?

A: Using die steel ensures excellent durability, extended service life, and consistent size reduction of materials, minimizing downtime and maintenance costs while delivering high-quality results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Disc Blades Category

Grindfroce Elite Disc Blades

Price 25000 INR / Set

Minimum Order Quantity : 1 Set

Size : 300 MM 600 MM

Color : BLACK

Product Type : INDUSTRIAL

Usage : Industrial

Pvc Pulverizer Disc Blade

Price 31000 INR / Pair

Minimum Order Quantity : 1 Pair

Size : 400mm

Color : Grey

Product Type : PULVERISER DISC BLADE

Usage : Grinding

Pulverizer Disc Manufacturer From Goa

Price 32000 INR / Pair

Minimum Order Quantity : 1 Pair

Size : Standard

Color : Grey

Product Type : PULVERISER DISC BLADE

Usage : Industrial

PVC Pulverizer Disc Blade

Price 31000 INR / Pair

Minimum Order Quantity : 1 Pair

Size : 400mm

Color : Grey

Product Type : PULVERISER DISC BLADE

Usage : Commercial

Send Inquiry

Send Inquiry