Pulverizer Disc Manufacturer From Goa

Price 32000 INR/ Pair

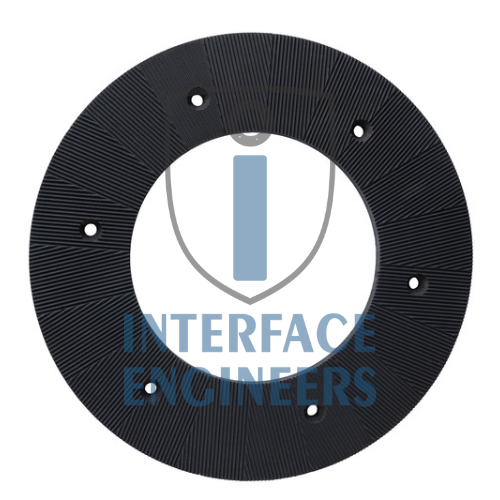

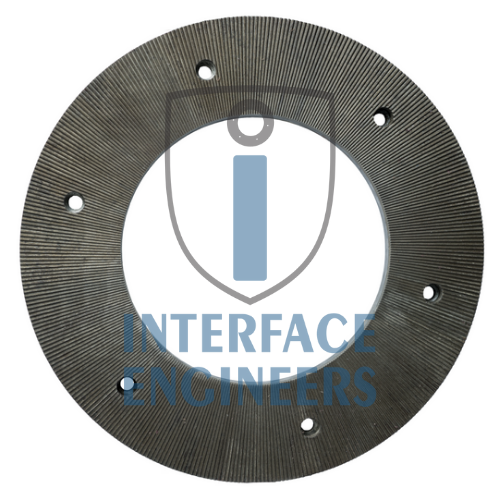

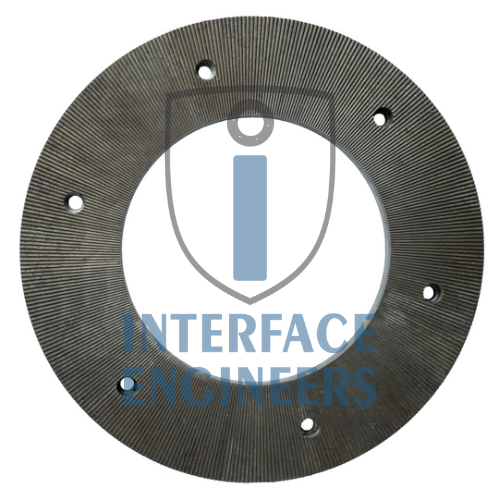

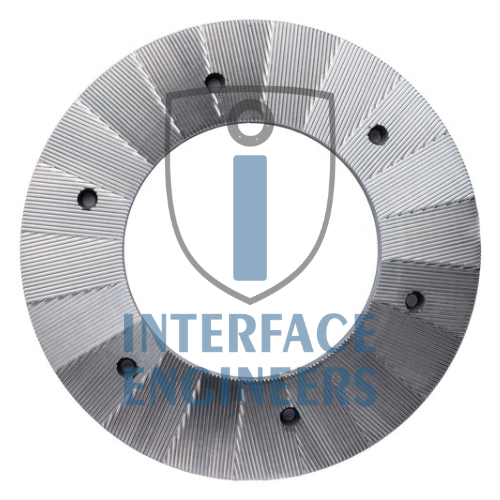

Pulverizer Disc Manufacturer From Goa Specification

- Shape

- Round

- Usage

- Industrial

- Size

- Standard

- Height

- 16 MM Millimeter (mm)

- Product Type

- PULVERISER DISC BLADE

- Weight

- 20-75 KG Kilograms (kg)

- Color

- Grey

- Width

- 50 MM Millimeter (mm)

- Length

- 30 MM Millimeter (mm)

Pulverizer Disc Manufacturer From Goa Trade Information

- Minimum Order Quantity

- 1 Pair

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pairs Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Pulverizer Disc Manufacturer From Goa

DISCBLADE FOR PULVERISER MACHINE.

SUITABLE FOR FINE POWDER PRODUCTION

OUR DISC BLADE CAN EASILY INCREASEMINIMUN 15 KG PER HOUR PRODUCTION IN YOUR EXISTING MACHINE.

OUR DISC BLADE IS SUITABLE FOR MATERIAL LIKE:

PVC SCRAP

LLDPE

RPVC

CPVC

UPVC

NATURAL RUBBER

ETC...

WE CAN SUPPLY OUR PRODUCT GLOBALLY. CURRENTNOTWORK OF BUSINESS IS INDIA , NEPAL , BHUTAN, AND CONTINUOUSLY EXPANDING.

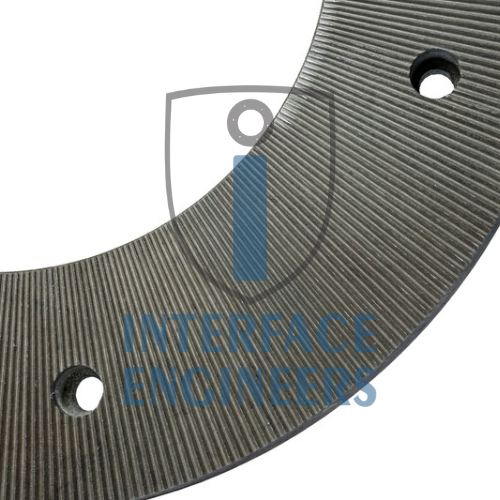

Durable Construction with TOOL STEEL (WPS/D2)

Our pulverizer discs are manufactured using high-grade TOOL STEEL (WPS/D2), known for its remarkable hardness and wear resistance. This material guarantees a longer lifespan and consistently high performance in demanding industrial situations.

Precision Engineering for Industrial Efficiency

With exact measurements 50 mm width, 16 mm height, and 30 mm length each disc is engineered for reliability and smooth function. Suitable for various industrial settings, our discs are designed for seamless integration and manual operation, conforming to standard sizes for effortless replacement.

FAQs of Pulverizer Disc Manufacturer From Goa:

Q: How is the Pulverizer Disc used in industrial applications?

A: The Pulverizer Disc is employed in machinery for grinding, crushing, or pulverizing materials in various industries. Its robust TOOL STEEL construction allows it to withstand rigorous use and deliver consistent results.Q: What benefits does TOOL STEEL (WPS/D2) offer compared to other materials?

A: TOOL STEEL (WPS/D2) provides superior hardness, wear resistance, and toughness, making the disc ideal for extended use in demanding environments. It significantly reduces maintenance requirements and replacement frequency.Q: Where can the Pulverizer Disc be utilized?

A: This disc is versatile and suitable for multiple industrial sectors, such as manufacturing, chemical processing, and food production facilities across India, where reliable grinding and pulverizing performance are crucial.Q: What is the manufacturing process for these discs?

A: The discs are produced through precision machining and heat treatment of TOOL STEEL (WPS/D2) to ensure exact dimensions, optimal hardness, and consistent quality.Q: When should the Pulverizer Disc be replaced?

A: Replacement is recommended when signs of excessive wear, reduced performance, or physical damage are noticed during regular equipment maintenance. Using new discs ensures operational safety and efficiency.Q: How does the manual power source benefit users?

A: A manual power source provides greater control, ease of use, and flexibility during operation, making these discs suitable for setups where electrical or automatic options are not feasible.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Disc Blades Category

LLDPE PULVERISER DISC BLADE

Price 20000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 2075 KG Kilograms (kg)

Usage : Industrial

Material : Hard Alloy

Size : 300 MM 600 MM

Lldpe Pulverizer Disc 450 MM Dia

Price 52000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 60 Kilograms (kg)

Usage : PVC POWDER MAKING

Material : D2/D3/W.P.S./IMPORTED/41B

Size : 450 MM

LLDPE PULVERIZER DISC

Price 33000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 41 Kilograms (kg)

Usage : LLDPE POWDER MAKING

Material : D2/D3/W.P.S./IMPORTED/41B

Size : 400 MM DISC

Pulverizer Disc

Price 330000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 2075 KG Kilograms (kg)

Usage : Industrial

Material : TOOL STEEL

Size : 300 MM 600 MM

Send Inquiry

Send Inquiry