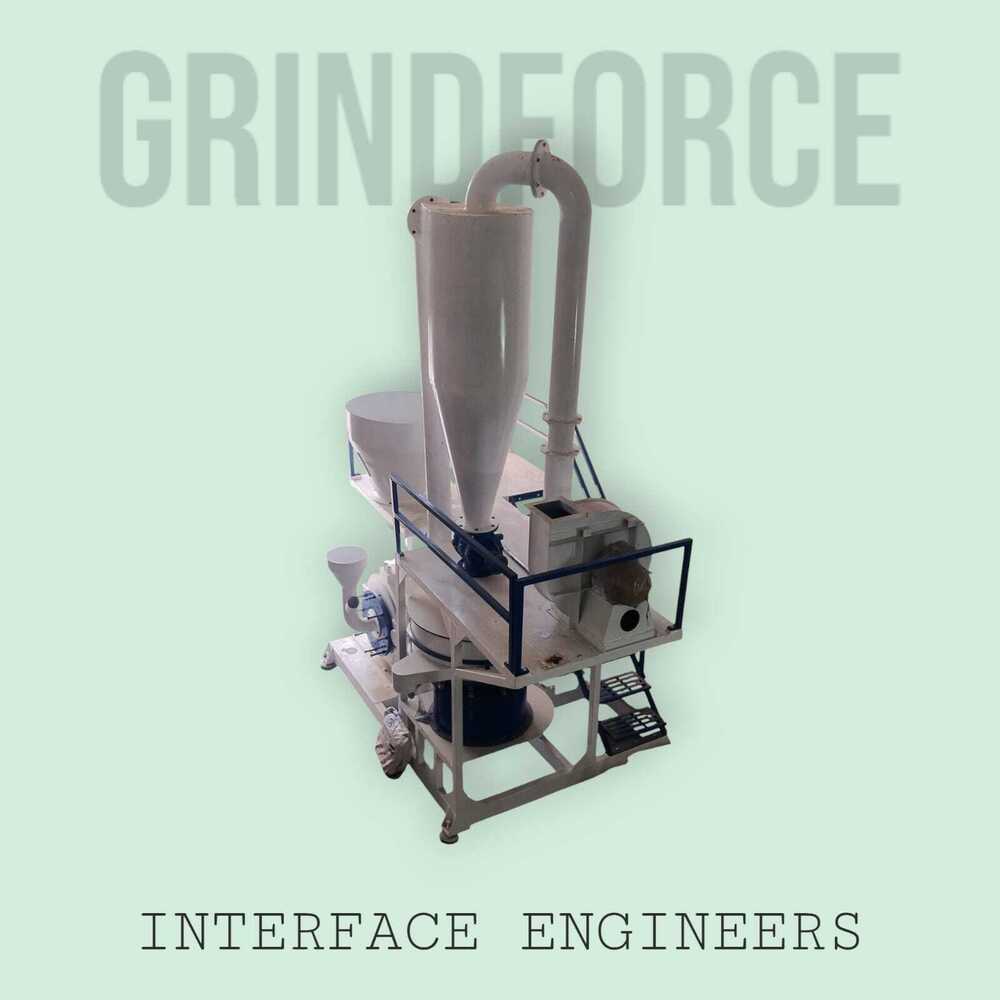

Rotomoulding Pulverizer Machine

Price 531000 INR/ Piece

Rotomoulding Pulverizer Machine Specification

- Usage

- Industrial

- Condition

- New

- Size

- 300 MM - 600 MM

- Material

- Mild Steel

- Height

- 11.5 Foot (ft)

- Power Source

- Electric

- Product Type

- INDUSTRIAL LLDPE PULVERISER MACHINE

- Power(W)

- 48 Horsepower (HP)

- Weight

- 1650 Kilograms (kg)

- Color

- Blue White

- Power Consumption

- 40 Horsepower (HP)

- Length

- 5.5 Foot (ft)

- Width

- 6 Foot (ft)

- Dimension (L*W*H)

- 11.5*5.5*5.5 Foot (ft)

Rotomoulding Pulverizer Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Rotomoulding Pulverizer Machine

The Plastic Pulverizer Machine (Disc Mill Type) is expertlyengineered to efficiently process PVC and LLDPE materials into fine,consistent powder. Its precision disc-based grinding system is ideal forproducing high-quality material essential for rotational molding, masterbatch,and other specialized applications.

High-Performance Pulverization System

This Pulverizer Machine delivers consistent and fine output, ideal for rotomoulding industries requiring granular plastic material for shaping tanks, containers, and other products. Its innovative design facilitates optimal material flow and efficient grinding, reducing downtime and operational costs. The meticulously engineered system ensures reliability and quality in every production cycle.

Robust Build and Efficient Power Usage

Constructed with high-grade mild steel, the machine offers durability and longevity under rigorous industrial use. Its electric-driven mechanism boasts a substantial 48 HP motor, utilizing 40 HP in operation for balanced performance and energy efficiency. The 300 MM to 600 MM size capacity caters to versatile processing needs, and the overall design prioritizes safety and ease of maintenance.

FAQs of Rotomoulding Pulverizer Machine:

Q: How does the Rotomoulding Pulverizer Machine process raw materials?

A: The machine utilizes an electric motor to grind and pulverize polymer materials. Raw plastic is fed into the hopper, where rotating blades efficiently reduce it to the desired granule size, ranging from 300 MM to 600 MM, suitable for rotomoulding applications.Q: What are the main benefits of using this pulverizer in industrial settings?

A: Key benefits include high throughput, consistent particle size, robust construction for durability, and energy-efficient operation. These features enhance material quality, speed up production, and reduce maintenance requirements in rotomoulding industries.Q: When should you consider upgrading to this new pulverizer model?

A: Upgrading is recommended when current equipment cannot meet production capacity or energy efficiency needs, or if greater consistency in granule size is required for quality rotomoulded products.Q: Where is this machine primarily installed and operated?

A: The machine is primarily installed in industrial manufacturing facilities across India, especially within plastics and polymer processing plants involved in rotomoulding operations.Q: What is the process of commissioning and maintaining this pulverizer?

A: Commissioning involves positioning the machine in a designated workspace, connecting to a compatible electric source, and calibrating settings for specific material types. Routine maintenance includes cleaning, inspecting wearing parts, and lubricating moving components to ensure smooth operation.Q: How is the machine supplied and who are the intended users?

A: It is available new from manufacturers, distributors, exporters, suppliers, and service providers in India. Intended users are businesses engaged in large-scale polymer processing, rotomoulding, and related industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Pulverizer Machine Category

Pvc Pulverizer Machine

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Consumption : 20150 HP Horsepower (HP)

Power(W) : 220/440 Volt (v)

Dimension (L*W*H) : 4.5 FT * 5.5 FT * 11 FT Foot (ft)

Material : Mild Steel

Cradit Card Pvc Pulverizer Machine

Price 425000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Consumption : 2075 HP Horsepower (HP)

Power(W) : 220/440 Volt (v)

Dimension (L*W*H) : 11.5*5.5*5.5 Foot (ft)

Material : Mild Steel

Disc Mill Type Pulverizer Machine

Price 800000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Consumption : 20150 HP Horsepower (HP)

Power(W) : 220/440 Volt (v)

Dimension (L*W*H) : 6FT * 5.5 FT * 15 FT Foot (ft)

Material : Mild Steel

Automatic PVC Plastic Pulverizer Machine For Industries

Price 850000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Consumption : 125 P Horsepower (HP)

Power(W) : 220/440 Volt (v)

Dimension (L*W*H) : 6FT * 5.5 FT * 15 FT Foot (ft)

Material : Mild Steel

Send Inquiry

Send Inquiry