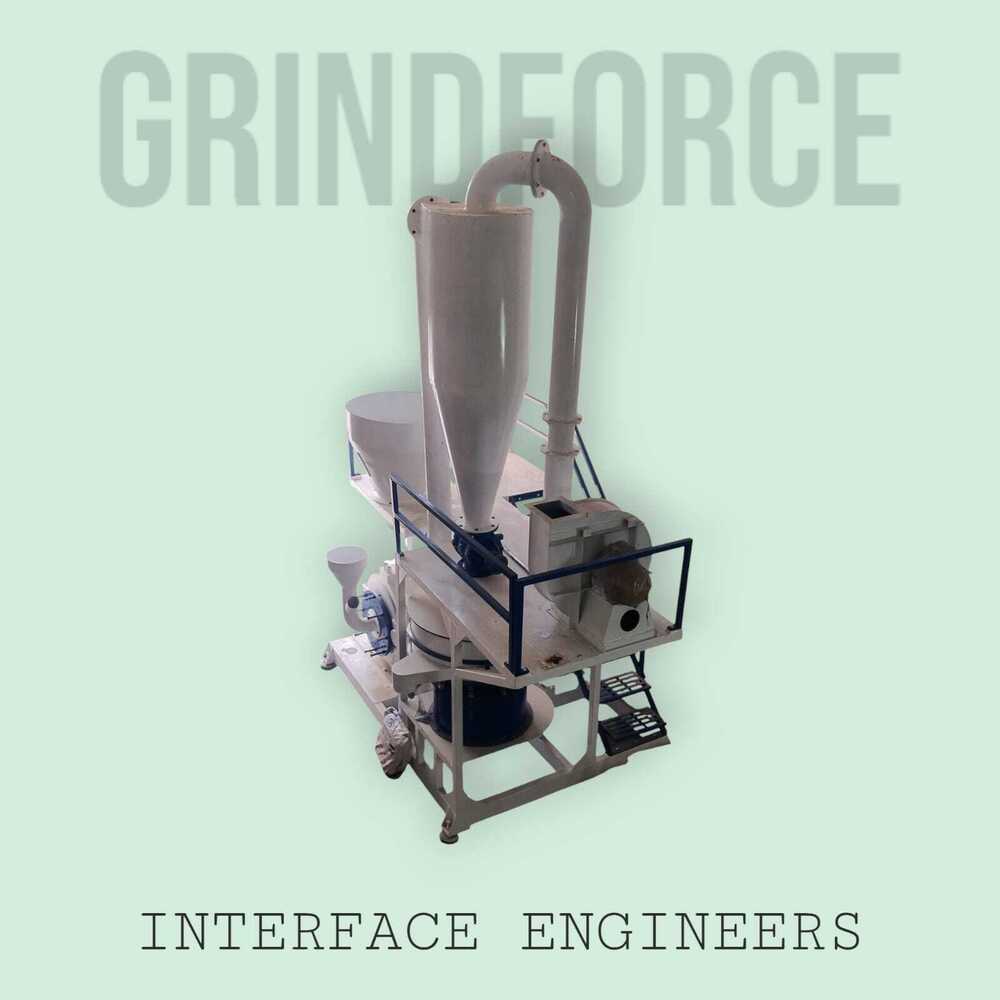

Pvc Pulverizer Machine

Price 580000 INR/ Piece

Pvc Pulverizer Machine Specification

- Usage

- Commercial

- Condition

- New

- Material

- Mild Steel

- Size

- 300 MM - 600 MM

- Height

- 11.5 Foot (ft)

- Power Source

- Electric

- Product Type

- INDUSTRIAL PULVERISER MACHINE

- Weight

- 1825 Kilograms (kg)

- Power(W)

- 50 Horsepower (HP)

- Power Consumption

- 40 Horsepower (HP)

- Color

- White and Blue

- Width

- 6 Foot (ft)

- Length

- 5.5 Foot (ft)

- Dimension (L*W*H)

- 6FT * 5.5 FT * 15 FT Foot (ft)

Pvc Pulverizer Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Pvc Pulverizer Machine

Achieve micro-fine powders from PVC and LLDPE with thishigh-performance Disc Mill Plastic Pulverizer. Designed for robustoperation, it provides efficient and consistent size reduction, meeting the stringentrequirements for CPVC PIPE, UPVC PIPE, and WATER TANK MFG. applications usingthese polymers.

Efficient PVC Pulverizing Technology

Equipped with a powerful 50 horsepower electric motor, this PVC Pulverizer Machine ensures consistent, fine pulverization of PVC materials for commercial purposes. Its sturdy mild steel construction and advanced technology deliver reliable performance and longevity.

Adaptable for Multiple Industrial Applications

Designed for flexibility, the machine handles PVC material sizes from 300 mm to 600 mm, making it suitable for various production and recycling processes. Its spacious dimensions and robust build support high-volume, demanding operations.

FAQs of Pvc Pulverizer Machine:

Q: How does the PVC Pulverizer Machine operate?

A: The machine uses a 50 HP electric motor to drive a specialized cutting mechanism that pulverizes PVC materials efficiently. With precise controls and durable blades, it ensures uniform particle size for commercial applications.Q: What are the main uses of this machine in industrial settings?

A: Primarily, the PVC Pulverizer Machine is used to grind PVC scraps or production waste into fine powder, suitable for reuse in manufacturing new PVC products or recycling operations.Q: When is it advisable to use this machine for processing PVC?

A: It is best used when there is a need to convert large volumes of PVC materialsuch as production scraps or post-consumer wasteinto reprocessable powder, which streamlines material recycling and reduces operational waste.Q: Where can this PVC Pulverizer Machine be installed and utilized?

A: Due to its substantial size and weight, the machine is typically installed in industrial environments like manufacturing plants, recycling units, or large-scale workshops.Q: What is the process involved in pulverizing PVC with this machine?

A: PVC materials are fed into the machines hopper. The motor powers the internal blades, which grind the PVC into fine powder. The processed material can then be collected for use in further production or recycling.Q: What are the benefits of using this machine for PVC processing?

A: The machine offers high efficiency, reduced manual labor, consistent output quality, and the ability to recycle and reclaim PVC material, making manufacturing processes more sustainable and cost-effective.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Pulverizer Machine Category

Pvc Thread Pulverizer Machine

Price 601000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 80 KG/HR 500 KG/HR

Usage : Industrial

Color : White

Condition : New

CPVC Plastic Pulverizer Machine

Price 580000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 300 MM 600 MM DISC

Usage : Industrial

Color : White and Blue

Condition : New

Pvc Pulverizer Machine With Dust Collector

Price 725000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 300 MM 600 MM

Usage : Commercial

Color : Gray & White

Condition : New

Natural Reprocess Pvc Pulverizer Machine

Price 561000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 300 MM 600 MM

Usage : Industrial

Color : Gray & White

Condition : New

Send Inquiry

Send Inquiry