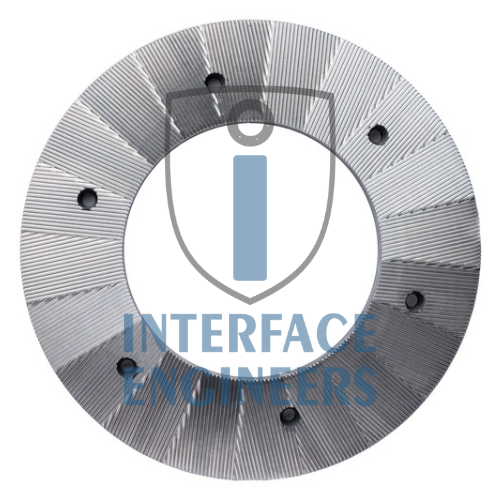

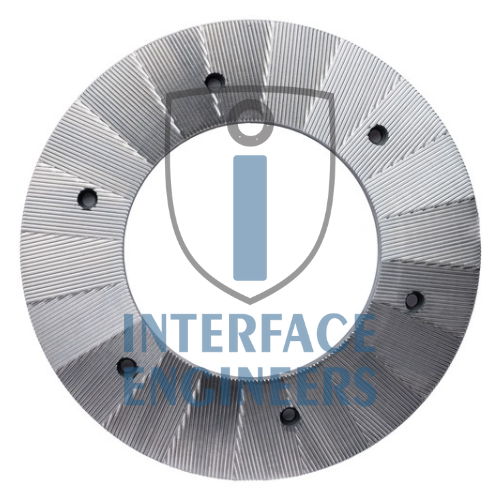

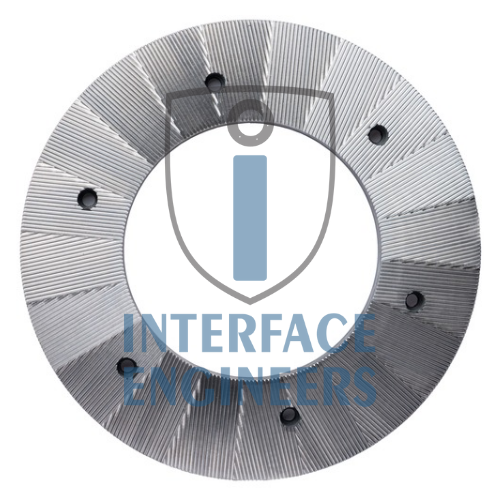

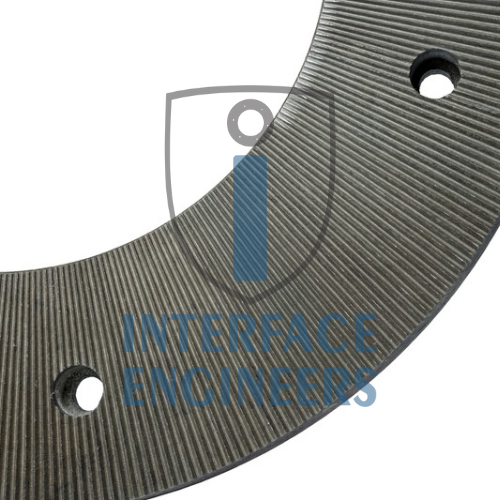

LLDPE Pulverizer Disc Blade

Price 30000 INR/ Pair

LLDPE Pulverizer Disc Blade Specification

- Usage

- Commercial

- Shape

- Round

- Size

- 300 MM - 600 MM DISC

- Product Type

- PULVERISER DISC BLADE

- Weight

- 20-75 KG Kilograms (kg)

- Color

- Grey

LLDPE Pulverizer Disc Blade Trade Information

- Minimum Order Quantity

- 1 Pair

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pairs Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About LLDPE Pulverizer Disc Blade

DISCBLADE FOR PULVERISER MACHINE.

SUITABLE FOR FINE POWDER PRODUCTION

OUR DISC BLADE CAN EASILY INCREASEMINIMUN 15 KG PER HOUR PRODUCTION IN YOUR EXISTING MACHINE.

OUR DISC BLADE IS SUITABLE FOR MATERIAL LIKE:

PVC SCRAP

LLDPE

RPVC

CPVC

UPVC

NATURAL RUBBER

ETC...

WE CAN SUPPLY OUR PRODUCT GLOBALLY. CURRENTNOTWORK OF BUSINESS IS INDIA , NEPAL , BHUTAN, AND CONTINUOUSLY EXPANDING.

Optimized Pulverization Performance

This disc blade is engineered to deliver optimal grinding and pulverizing efficiency, thanks to its advanced design and die steel construction. Users benefit from extended lifespan, minimal downtime, and consistent results in heavy-duty commercial operations.

Wide Applicability

Available in multiple sizes, the blade supports various pulverizer models and industrial setups. It caters to manufacturers, suppliers, and service providers who require reliability, precision, and adaptability for different processing requirements.

FAQs of LLDPE Pulverizer Disc Blade:

Q: How is the LLDPE Pulverizer Disc Blade used in commercial applications?

A: The blade is mounted in pulverizer machines to grind and process LLDPE and similar materials. Its manual operation allows users to adjust and control the pulverization process for efficient material handling in manufacturing environments.Q: What materials are used in the construction of the disc blade?

A: The LLDPE Pulverizer Disc Blade is crafted from high-quality die steel, ensuring resistance to wear and a prolonged service life, suitable for continuous commercial usage.Q: Where can this disc blade be installed or operated?

A: It fits within pulverizer units used in factories, processing plants, and other industrial settings where LLDPE material grinding is required, adaptable to environments in India and beyond.Q: When is it beneficial to replace the disc blade?

A: Replacement is recommended when the blade shows visible signs of wear, reduced performance, or after extended usage. Regular assessment ensures efficient operation and prevents process disruptions.Q: What is the typical process for installing the blade?

A: Installation involves securing the round disc within the pulverizer chamber, aligning it according to the machine specifications and ensuring tight fitting for safe and effective operation.Q: What are the advantages of using a manual power source for this disc blade?

A: Manual operation offers users precise control over the pulverization process, allowing for adjustments as needed to cater to various material properties and production requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Segments Type Disc Blades Category

MASTERBATCH DISC BLADE

Price 25000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 2075 KG

Product Type : INDUSTRIAL PULVERISER DISC BLADE

Material : Hard Alloy

Color : BLACK

Segments Type Disc Blades

Price 30000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 20 KG TO 100 KG Kilograms (kg)

Product Type : PULVERISER DISC BLADE

Material : Hard Alloy

Color : BLACK

Wps D2 & D3 Lldpe Pulverizer Blade

Price 26000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 32 Kilograms (kg)

Product Type : PULVERISER DISC BLADE

Material : D2/D3/W.P.S./IMPORTED/41B

Color : BLACK

Pulverizer Disc

Price 33000 INR / Set

Minimum Order Quantity : 1 Set

Weight : 2075 KG Kilograms (kg)

Product Type : PULVERISER DISC BLADE

Material : D2/D3/W.P.S./IMPORTED/41B

Color : Grey

Send Inquiry

Send Inquiry