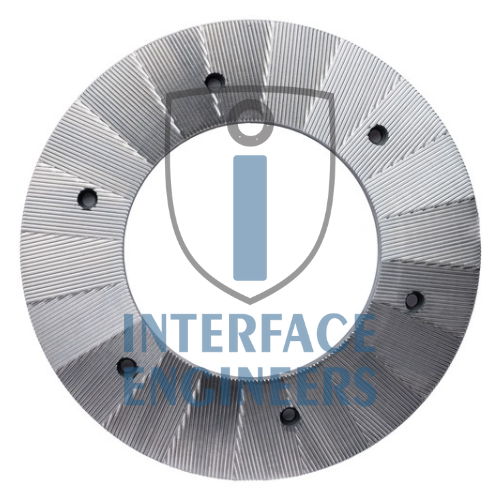

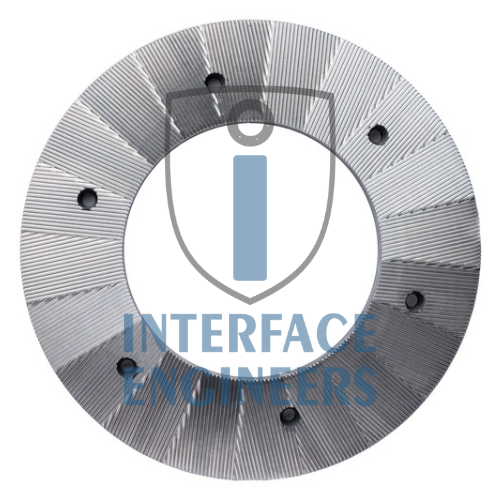

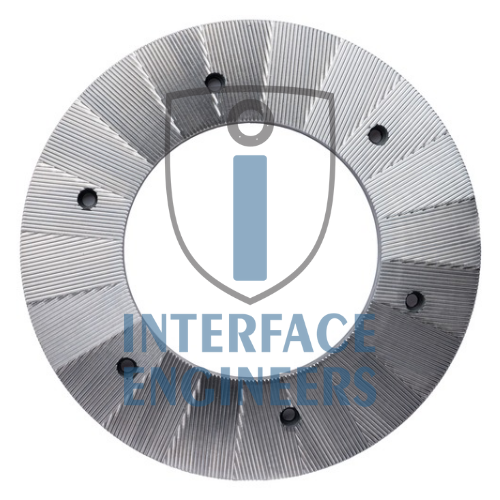

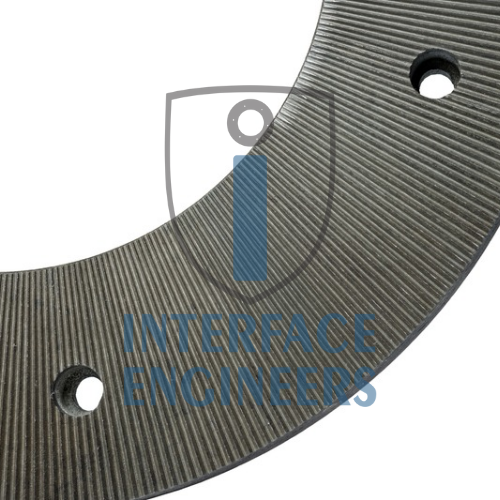

LLDPE Pulverizer Disc Blade

Price 28000 INR/ Pair

LLDPE Pulverizer Disc Blade Specification

- Shape

- Round

- Usage

- Industrial

- Size

- 300 MM - 600 MM DISC

- Product Type

- PULVERISER DISC BLADE

- Weight

- 20-75 KG Kilograms (kg)

- Color

- Grey

LLDPE Pulverizer Disc Blade Trade Information

- Minimum Order Quantity

- 1 Pair

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pairs Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About LLDPE Pulverizer Disc Blade

DISCBLADE FOR PULVERISER MACHINE.

SUITABLE FOR FINE POWDER PRODUCTION

OUR DISC BLADE CAN EASILY INCREASEMINIMUN 15 KG PER HOUR PRODUCTION IN YOUR EXISTING MACHINE.

OUR DISC BLADE IS SUITABLE FOR MATERIAL LIKE:

PVC SCRAP

LLDPE

RPVC

CPVC

UPVC

NATURAL RUBBER

ETC...

WE CAN SUPPLY OUR PRODUCT GLOBALLY. CURRENTNOTWORK OF BUSINESS IS INDIA , NEPAL , BHUTAN, AND CONTINUOUSLY EXPANDING.

Precision Engineering for Industrial Efficiency

Engineered from premium TOOL STEEL (WPS/D2), the LLDPE Pulverizer Disc Blade guarantees excellent durability and performance in demanding environments. The disc fits industrial pulverizing machines and is suitable for a wide range of manufacturing setups, providing consistent, efficient material processing. Its optimal design minimizes downtime, maintaining process continuity and product quality.

Versatile Sizing and Application Range

Available in diameters from 300 mm to 600 mm and weighing between 20 and 75 kilograms, this disc blade accommodates different machine settings and production requirements. Its robust construction allows usage in various sectors involving plastics processing, recycling, and material reduction. Ideal for distributors, manufacturers, and service providers across India.

FAQs of LLDPE Pulverizer Disc Blade:

Q: How is the LLDPE Pulverizer Disc Blade typically used in industrial applications?

A: The disc blade is installed in pulverizing machines to grind Linear Low Density Polyethylene and similar materials into fine powder. Its sharp, round edges ensure uniform material size, which is crucial for molding, recycling, or further processing.Q: What process is involved in producing the LLDPE Pulverizer Disc Blade?

A: The manufacturing process uses TOOL STEEL (WPS/D2), which undergoes precision machining and hardening treatments to achieve optimal sharpness, strength, and longevity, ensuring high-performance cutting under heavy industrial use.Q: Where can this disc blade be sourced in India?

A: The LLDPE Pulverizer Disc Blade is available from a wide network of distributors, exporters, importers, manufacturers, service providers, suppliers, traders, and wholesalers across India. Orders can typically be placed directly through these channels.Q: When should the disc blade be replaced in a pulverizer?

A: The disc blade should be monitored for wear or reduced efficiency during operation. Replacement is recommended when there is visible dullness, chipping, or a drop in material processing quality to maintain optimal performance.Q: What are the main benefits of choosing a TOOL STEEL (WPS/D2) disc blade?

A: TOOL STEEL (WPS/D2) offers excellent wear resistance, hardness, and durability, making it ideal for continuous industrial use. This results in longer service life, reduced maintenance interruptions, and reliable performance.Q: How can users ensure proper installation and performance of the disc blade?

A: Users should follow the machine manufacturers guidelines for installation, ensuring the disc is securely fitted and correctly aligned. Routine inspections and regular cleaning help maintain peak efficiency and safety during operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Segments Type Disc Blades Category

Segments Type Disc Blades

Price 30000 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Weight : 20 KG TO 100 KG Kilograms (kg)

Product Type : PULVERISER DISC BLADE

Color : BLACK

MASTERBATCH DISC BLADE

Price 25000 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Weight : 2075 KG

Product Type : INDUSTRIAL PULVERISER DISC BLADE

Color : BLACK

Pulverizer Disc

Price 33000 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Weight : 2075 KG Kilograms (kg)

Product Type : PULVERISER DISC BLADE

Color : Grey

Wps D2 & D3 Lldpe Pulverizer Blade

Price 26000 INR / Set

Minimum Order Quantity : 1 Set

Usage : LLDPE POWDER MAKING

Weight : 32 Kilograms (kg)

Product Type : PULVERISER DISC BLADE

Color : BLACK

Send Inquiry

Send Inquiry